Colloidal Silver Nano Silver Solution CAS 7440-22-4

About Colloidal Silver Nano Silver Solution:

Nano Silver solution is a metallic Silver elemental with a particle size of 1-100nm. The particle size of the nanosilver is mostly about 20 nanometers, and a few can reach less than 5 nanometers. With a broad spectrum of bactericidal effects, about 650 kinds of bacteria, and do not produce drug resistance. Animal experiments showed that even if the dosage of nano-silver antibacterial powder reached thousands of times aboutthe standard dosage, the tested animals had no toxic performance. At the same time, it can also promote the repair of damaged epithelial cells. It is worth mentioning that the antibacterial effect of this product is increasingly enhanced when it meets water, which is more conducive to the treatment of diseases.

Nano-silver acting on cell membrane proteins can directly destroy bacterial cell membrane and oxygen metabolism enzyme (-SH), block bacteria and other microorganisms from the absorption of amino acids, uracil and other essential nutrients for growth, thus inhibiting their growth. This unique mechanism can kill most bacteria, fungi and other microorganisms. Nano-silver particles have super permeability and can quickly penetrate into the subcutaneous 2mm to sterilize, which has a good bactericidal effect on the deep tissue infection caused by common bacteria, stubborn bacteria, drug-resistant bacteria and fungi. Orachemicals is a trusted global Colloidal Silver Nano Sliver Solution supplier. Feel free to send an inquiry about the latest price of Nano Silver at any time.

Product Performance of Colloidal Silver Nano Silver Solution CAS 7440-22-4:

The nanosilver solution is a colorless & transparent liquid or light yellow, made of nanosilver that particle size is less than 2nm through nanotechnology.

The colloidal silver is widely applicable for various fabrics including cotton, blending fabric, chemical fiber, non-woven fabric, leather, etc for washing-resistance antimicrobial purposes. Textile after treating will not affect origin handling, color or state, and the antimicrobial effect can maintain above 99% even after washing 50 times.

Technical Parameter of Colloidal Silver Nano Silver Solution:

| Product Name | MF | Purity | Particle Size | Bulk Density | Melting Point | Color |

| Colloidal Silver | Ag | 100ppm,1000ppm | <10nm | 10.49 g/cm3 | 961℃ | light yellow |

How is Colloidal Silver Nano Silver Solution Produced?

The invention relates to a preparation method of nano-silver solution, in which the weight to part ratio of the main raw materials is AgNO3: reducing agent: Gellan glue: auxiliary agent: surfactant =0.8 ~ 1.2:0.8 ~ 0.5:0.5 ~ 1.8:1.8 ~ 2.2:2.8 ~ 3.2. Preparation steps: prepare the aqueous solution of AgNO3 and reducing agent respectively for standby; Mixed Gellan Gellan with NaCl or sugar according to the weight/part ratio of Gellan: NaCl/ sugar = 1:9-11, put it into the reactor of high shear dispersion emulsifier in the ultrasonic field, add water, heat it to 50 ~ 70℃, rotate speed of 500 ~ 700rpm/min, and stir to prepare mixed solution A. Add the auxiliary agent, continue to stir and mix; The surfactant was dissolved in hot water, and then added to the reactor, and continued to be stirred and mixed at a speed of 500 ~ 700rpm/min. The water solution of AgNO3 and the reducing agent was pumped into the reactor, the rotating speed was increased to 2000 ~ 3000rpm/min, and the nanometer silver solution with a particle size of 3 ~ 60 nm was prepared by continuous stirring for 0.5 ~ 24 hours.

Applications of Colloidal Silver Nano Silver Solution:

Colloidal nanosilver can be used in medical and health care, medical equipment, textile, paint, daily necessities, cosmetics, flowers, ecological environment and other fields.

1. Antibacterial finishing of textiles, paper products, leather and sponges;

2. Antibacterial and deodorant treatment for all kinds of shoes, toys and daily necessities;

3. It is suitable for antibacterial deodorization of various waterborne and oil-based coatings;

4. Widely used in the medical field: fungicides, medical hose, colloidal silver, lotions, tablets; Soap, cleaning supplies; Chemical building materials; Plastic products;

5. Nano colloidal silver can be added to PE, PP, PC, PET, ABS and other plastics to achieve antibacterial function.

Storage Condition of Colloidal Silver Nano Silver Solution:

Colloidal silver nanosilver solution should be sealed in vacuum packing and stored in a cool and dark place to avoid moisture and sunshine.

Packing & Shipping of Colloidal Silver Nano Silver Solution:

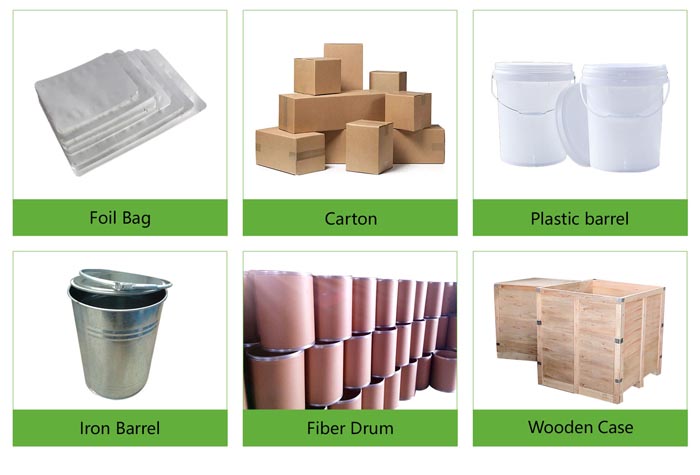

We have many different kinds of packing which depend on the colloidal silver quantity.

Colloidal Silver Nano Silver Solution packing: 30ml/ bottle, 100ml/ bottle, 250ml/ bottle, or as your request.

Colloidal Silver Nano Silver Solution shipping: could be shipped out by express, by air, by air as soon as possible once payment receipt.

Colloidal Silver Nano Silver Properties | |

| Other Names | Colloidal Silver, Nano Silver, silver nano liquid |

| CAS No. | 7440-22-4 |

| Compound Formula | Ag |

| Molecular Weight | N/A |

| Appearance | colorless & transparent liquid or light yellow |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | 10.49 g/cm3 |

| Purity | 100ppm, 1000ppm, 2000ppm |

| Particle Size | <10nm |

| Boling point | 961℃ |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

Colloidal Silver Nano Silver Health & Safety Information | |

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |