Cerium Nitride CeN Powder CAS 25764-08-3

About Cerium Nitride CeN Powder:

Cerium Nitride is a brown powder with the chemical formula CEN and a molecular weight of 154.11g/mol. Rare earth elements, known as "industrial vitamins", are extremely important strategic resources. Cerium Nitride is widely used in petroleum, chemical industry, metallurgy, textile, ceramics, glass, permanent magnet materials and other fields. Therefore, it is very important to study rare earth compounds.

Cerium Nitride is a brown powder with a NaCl-type structure (A =0.501nm) and is soluble in acids. Stabilizes at high temperatures and releases ammonia. It reacts with alkali in an electric arc furnace. Cerium nitride is dangerous when wet. Cerium sheet or Cerium metal is the raw material. Feel free to send an inquiry to get the latest price if you would like to buy Cerium Nitride CeN Powder in bulk.

Product Performance of Cerium Nitride CeN powder:

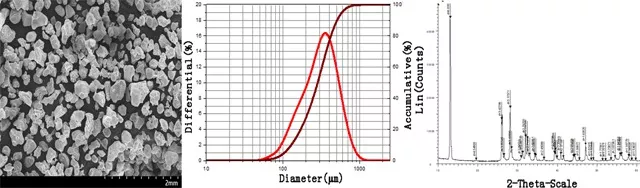

Our cerium nitride CeN powder (CAS 25764-08-3) is with high purity, ultrafine particle size, bigger surface area.

Technical Data of Cerium Nitride CeN powder:

| Part Name | High Purity Cerium Nitride Powder |

| MF | CeN |

| Purity | 99.5% |

| Particle Size | -100 mesh |

| Application | Cerium nitride CeN powder is used in high-end ceramics, luminescent materials, special metallurgy, etc. |

Specification of Cerium Nitride CeN powder:

| Part Name | Cerium Nitride CeN Powder |

| Appearance | Brown Powder |

| Purity | 99.5% |

| Ca (wt%) | 0.0026 |

| Fe (wt%) | 0.0032 |

| Si (wt%) | 0.0013 |

| C (wt%) | 0.001 |

| Al (wt%) | 0.0021 |

| Mg (wt%) | 0.0007 |

How is Cerium Nitride CeN Powder produced?

Ce powder with a purity of 99wt% was pretreated and mixed with additives, and then sintered in a specific reaction atmosphere. The sintered product was fully ground and then mixed with additives and additives for the second time. Finally, the surface treatment of the obtained cerium nitride powder was carried out.

Applications of Cerium Nitride CeN Powder:

Cerium Nitride powder is a kind of semiconductor material, photoelectric material, refractory material and ceramic material. It is widely used in petroleum, chemical industry, metallurgy, textile, ceramics, glass, permanent magnet materials and other fields.

Packing & Shipping of Cerium Nitride CeN powder:

We have many different kinds of packing which depend on the cerium nitride CeN powder quantity.

Cerium nitride CeN powder packing: vacuum packing, 1kg/bag, 25kg/barrel, or as your request.

Cerium nitride CeN powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Cerium Nitride CeN Powder Properties | |

| Other Names | nitridocerium, azanylidynecerium, cerium mononitride, cerium nitride, CeN powder |

| CAS No. | 25764-08-3 |

| Compound Formula | CeN |

| Molecular Weight | 154.123 |

| Appearance | Solid |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | N/A |

| Purity | 99.50% |

| Particle Size | -100 mesh |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | 153.908513 g/mol |

| Monoisotopic Mass | 153.908513 g/mol |

Cerium Nitride CeN Powder Health & Safety Information | |

| Safety Warning | Warning |

| Hazard Statements | H315-H319-H335 |

| Flashing point | N/A |

| Hazard Codes | Xi |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | NONH for all modes of transport |

| WGK Germany | N/A |