Product name: Ethylene bis stearamide emulsion

Formula: C38H76N2O2

Product property: It is produced by advanced technology and its appearance is white emulsion. The product is non-toxic, non-polluting, non-hazardous and environmentally friendly. Easy to disperse in water, with ultra-fine, low-viscosity, good dispersion and compatibility.

About EBS Ethylene Bis Stearamide Emulsion:

EBS emulsion is a white lotion. Ebs Ethylene Bis Steramide is a hard-brittle white high melting point wax, and its industrial products show slightly yellow fine particles, non-toxic, no side effects on the human body, not soluble in most solvents at normal temperature, can be stable for acid-base and water. Soluble hydrocarbons and aromatic hydrocarbon solvents, the powder is strong, with a compound having wettability of water at 80 ° C or higher.

EBS is an abbreviation for Ethylene Bis Steramide, is a high melting point synthetic wax, and the two-pole key maintains a highly balanced, its inherent structure plays unique compatibility and solubility, which can be used as most thermoset, thermoplastic. Lubricants and outer lubricants are good pigment dispersants that make the operation smooth and improve the quality of the final product.

Ebs Ethylene Bis Steramide is a newly developed plastic lubricant, which is widely used in PVC products, ABS, high-resistant polystyrene, polyolefin, rubber, plastic product molding, which is related to traditional lubricants such as paraffin. Compared to lubricants such as polyethylene wax, stearate, not only have good external lubrication but also has good internal lubrication, such that the fluidity and demolding of the fused plastic are improved in plastic molding. Thereby, the yield of plastic processing is increased, and energy consumption is reduced, and the product has a very high surface finish, smoothness. Feel free to send an inquiry to get the latest price if you would like to buy EBS Ethylene Bis Stearamide emulsion in bulk.

Properties of Ethylene bis stearamide emulsion:

EBS Ethylene Bis Stearamide Emulsion is a white emulsion, the product is non-toxic, non-polluting, non-hazardous, and environmentally friendly. It is easy to disperse in water and has the characteristics of superfine, low viscosity, good dispersion and compatibility.

How is EBS Ethylene Bis Stearamide produced?

The synthesis method of EBS can generally be divided into four routes:

Stearic acid reaction with amine compounds;

The stearate reaction is reacted with an amine compound;

Hardy chloride and amine compounds;

Hydrolysis of nitrile.

The most commonly used are the first and second types. The first method is simple, the reaction conditions are not demanding, no three disruptions, but low purity; although the EBS is high, the energy consumption is complex, the process is complex, and the process is long.

Application of EBS Ethylene Bis Stearamide Emulsion:

EBS Ethylene Bis Stearamide Emulsion is a white emulsion, the product is non-toxic, non-polluting, non-hazardous, and environmentally friendly. It is easy to disperse in water and has the characteristics of superfine, low viscosity, good dispersion and compatibility.

1.Plastic

In many thermoplastic and thermoset plastics, as internal and external sliding agents, the most representatives such as ABS, PS, AS, PVC, are also available in PE, PP, PVAC, Cellulose, Accurate, Nylon. , Phenolic-resin, amino plastic, etc., have good finishes and release property.

In thermoplastic PUR injection molding, the auxiliary agent also serves as an internal release agent, and the amount is 0.1 to 1%.

As the polymethylene gulf agent, the amount of addition is 0.5%, and the melt flow rate is increased, and the whiteness, thermal stability and the physical indicators of polyoxymethylene, and the physical indicators are improved.

2. Rubber

Synthetic resins and rubber, Polychloroprene, GRS (SBR) add 1 to 3% EBS in their emulsion, have good anti-stick and anti-blocking effects, EBS is applied to the automotive floor mat, drainage pipe and other rubber products It plays an effect of increased surface gloss.

3. Chemical fiber

EBS can increase the heat resistance, fluidity of polyester, polyamide fibers, and impart a certain antistatic effect.

4. Type

Casting sand is added with a phenol resin to add EBS as an exemplary agent.

5. Pigment, filler dispersant

EBS as plastic. Pigment dispersing agent of chemical fiber parent, such as ABS, PS, polypropylene, polyester pellets.

EBS can also be used as a plastic coloring spread powder.

According to the amount of the pigment filler, the amount added is 0.5 to 5%.

6. Powder coating

EBS can be used as a liquid aid for powder coatings.

7. Coatings, inks

When paint and paint are manufactured, add 0.5 ~ 2% EBS to improve salt fog and moisture-proof effect; adding this product in the paint to improve deleted agent performance, increases the level of the baking porcelain surface.

It can be used in furniture polishing agents and printing inks.

8. Other uses

The melting point of petroleum products;

Lubricants and corrosion agents during metal wire; potting materials for electrical components;

Above the papermaking agent and paper coating ingredients;

Dyeing in textile dyeing can be used as a dyeing engineering defoamer and a permanent water drawing agent;

Add this product to the asphalt, reduce the viscosity of the asphalt, improve the softening point, water-resistance and weather resistance of the asphalt.

Technical Data of Ethylene bis stearamide emulsion:

| Item | EB-20 |

| Solid content, % | 20±2 |

| Viscosity, cps | ≤100 |

| Particle size D50 | ≤2um |

| PH | 7-9 |

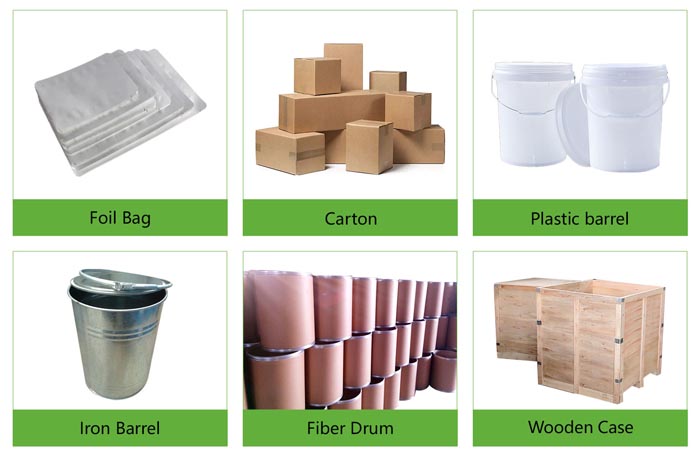

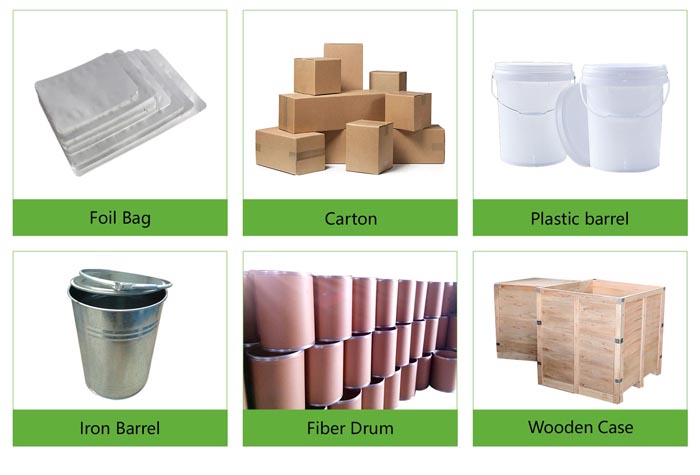

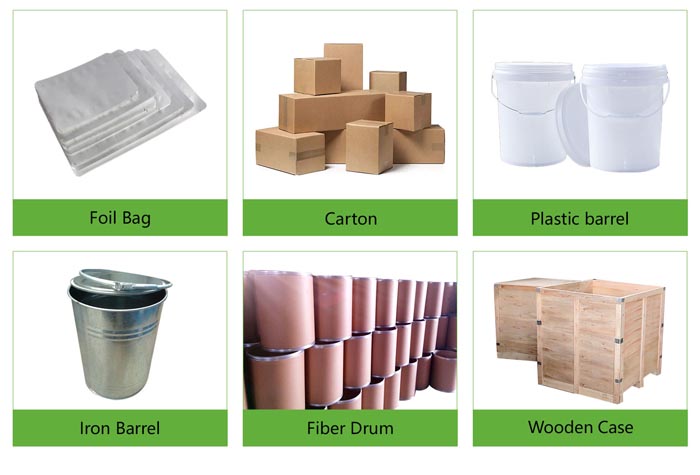

Packing & Shipping of Ethylene bis stearamide emulsion:

We have many different kinds of packing which depends on the Ethylene Bis Stearamide Emulsion quantity.

Ethylene Bis Stearamide Emulsion packing: 25kg/barrel, or as your request.

Ethylene Bis Stearamide Emulsion shipping: could be shipped out by sea , by air, by express as soon as possible once payment receipt.

EBS Ethylene Bis Stearamide Emulsion Properties |

| Other Names | 1,2-Bis(stearoylamino) ethane N,N’-1,2, Ethanediylbisoctadecanamide,

N,N’-Ethylenedi(stearamide), Ethylene distearylamide |

| CAS No. | N/A |

| Compound Formula | C38H76N2O2 |

| Molecular Weight | 593.038 g·mol−1 |

| Appearance | White, waxy crystals |

| Melting Point | 144 to 146 °C |

| Solubility in water | N/A |

| Density | N/A |

| Purity | N/A |

| Particle Size | D50: ≤2μm |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

| | |

| | |

EBS Ethylene Bis Stearamide Emulsion Health & Safety Information |

| Safety Warning | Warning |

| Hazard Statements | H315, H319, H335 |

| Flashing point | 280 °C |

| Hazard Codes | T |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Inquiry us