Gallium Nitride GaN powder CAS 25617-97-4

About Gallium Nitride GaN powder:

Gallium Nitride (GaN) is a hard, mechanically stable semiconductor compound with high heat capacity and thermal conductivity. It has a band gap of 3.4 eV and is crack resistant in its pure form.

Properties of Gallium Nitride:

| CAS No. | CAS 25617-97-4 |

| Purity | ≥99.99% |

| CAS Number | 25617-97-4 |

| Appearance | Yellow powder |

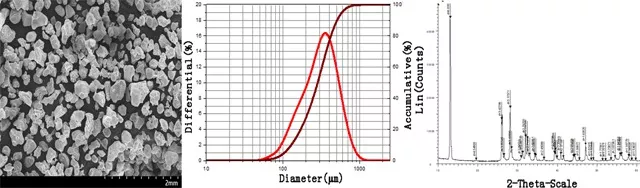

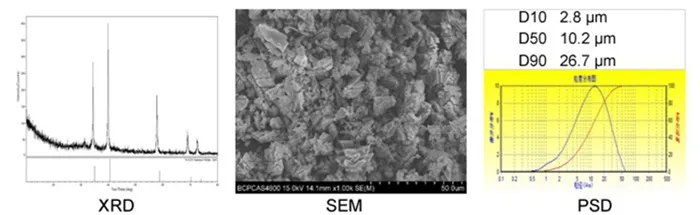

| X-Ray Diffraction | Conforms to Structure |

| Trance Metal Analysis | 200 ppm |

Its low sensitivity to ionizing radiation (with another group of III-nitrides) makes it a suitable material for satellite solar cell arrays. Military and spatial applications may also benefit because the equipment exhibits stability in the radiation environment.

Because the GaN transistor can operate at a higher temperature and operate at a high voltage than the arsenide (GaAs) transistor, they produce an ideal power amplifier at microwave frequencies. In addition, GAN also provides a hoped feature for THz devices. Due to high power density and voltage breakdown restrictions, GaN is also revealed as a hopeful candidate for 5G cellular base stations.

The research and application of GaN materials are the frontier and hotspots of global semiconductor research. It is a new semiconductor material developing microelectronic devices, optical electronics, and semiconductor materials such as SiC, diamonds, which are known as the first generation of GE, Si A third-generation semiconductor material after semiconductor material, second-generation GaAs, InP compound semiconductor material. It has a wide direct bandgap, strong atomic bond, high thermal conductivity, high chemical stability (almost no sour corrosion), etc., in light electrons, high-temperature high power devices and high-Frequency microwave device application has broad prospects. Feel free to send an inquiry to get the latest price if you would like to buy Gallium Nitride GaN powder in bulk.

Product Performance of Gallium Nitride powder:

GaN powder has a wide direct bandgap, strong atomic bonds, high thermal conductivity, good chemical stability (almost no acid corrosion) and other properties and strong anti-radiation ability in optoelectronics, high temperature and high power devices and high-frequency microwave device applications have a broad prospect.

Technical Parameter of Gallium Nitride GaN powder:

| Product Name | MF | Purity | Particle Size | Melting Point | Density | Color |

| gallium nitride | GaN | 99.99% | -60 mesh | 1700℃ | 6.1g/mL,25/4℃ | light yellow |

Chemical Composition of Gallium Nitride GaN powder:

| GaN | Cu | Ni | Zn | Al | Na | Cr | In | Ca |

| 99.99% | 0.0005% | 0.0003% | 0.0005% | 0.001% | 0.0005% | 0.0003% | 0.0005% | 0.005% |

How is Gallium Nitride GaN powder produced?

Gallium nitride is a Group III-V semiconductor and has a very high chemical resistance to corrosive environments. There is a firm bond between Ga and nitrogen, which is the cause of the corrosion resistance of the compound. Ballium nitride is a direct bandgap semiconductor (bandgap = 3.4 having a fibrous mineral structure EV) and is a material for producing a corrosive ambient light-emitting device. Gallium nitride is prepared by reacting Ga2O 3 with NH3 at a high temperature of about 1000 ° C.

Ga 2 O 3 + 2 NH 3 → 2 GaN + 3H 2 O

An organometallic compound containing Ga and a nitrogen atom can also be deposited by the chemical gas phase. X-ray diffraction and conductivity measurements indicate that corrosive acids and alkaline environments have no effect on the GaN phase.

Applications of Gallium Nitride GaN powder:

Since 1990, GaN has been commonly used as a light-emitting diode (LED). The blue light emitted by gallium nitride is that gallium nitride is a binary III/V direct bandgap semiconductor, which is very suitable for high-power transistors that can work at high temperatures. Used for Blu-ray disc reading. Gallium nitride is also used in semiconductor power devices, radio frequency components, lasers and photonics. In the future, we will see gallium nitride in sensor technology.

1. GaN may be used for large TV screens or smaller full-color panels in trains or buses. GaN-based LEDs are more efficient and therefore offer another possibility for blue and green LEDs.

2. Gallium nitride is used in power semiconductor fields such as electric vehicles and photovoltaics.

3. Gallium nitride is used in the 5G radiofrequency field. Due to the increased requirements for radio frequency power and energy consumption in 5G, the 5G radiofrequency field will gradually replace silicon-based materials with gallium nitride.

4. GaN is used in the field of fast charging of mobile phones. GaN chargers have the characteristics of large power, small size and high efficiency, which are the key to the breakthrough of super-fast charging technology.

Packing & Shipping of Gallium Nitride GaN powder :

We have many different kinds of packing which depend on the gallium nitride GaN powder quantity.

Gallium nitride GaN powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Gallium nitride GaN powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Gallium Nitride Properties | |

| Other Names | gallium nitride powder, GaN, GaN powder, gallium mononitride |

| CAS No. | 25617-97-4 |

| Compound Formula | GaN |

| Molecular Weight | 83.73 |

| Appearance | Light Yellow Powder |

| Melting Point | 1700 °C |

| Boiling Point | N/A |

| Density | 6.1 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 82.9287 |

| Monoisotopic Mass | 82.9287 |

Aluminum Nitride Health & Safety Information | |

| Signal Word | Warning |

| Hazard Statements | H317 |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | 22-24/25 |

| RTECS Number | LW9640000 |

| Transport Information | N/A |

| WGK Germany | 3 |