About The Preparation Method And Overview Of Aluminum Carbide

Aluminum Carbide

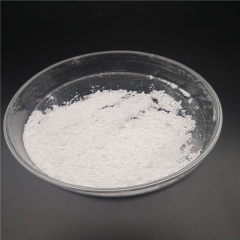

Aluminum carburide also known by the name three-carbon-four-aluminum has a molecular form of AL4C3, a kind aluminum carbide. It is a transparent, hard, light yellow-brown crystal. It is a ionic, non-conducting crystal at room temperature.

Aluminum Carbide:

Calcium carbide contains a small amount aluminum carbide. Aluminum carbide is often produced by corroding graphite electrodes when metal aluminum is melted using electrolysis. Aluminum carbide can be an undesirable component of metal matrix composites, or carbon fibres that use aluminum to create a matrix and then increase the strength by using carbides. Carbon fiber and aluminum composites are examples of materials that can react when the temperature is above 500. It can be prevented from reacting chemically if it is coated with a titanium boride layer. In the silicon carbid reinforced aluminum-based material, the chemical reactions between silicon and aluminum melt produce a layer or aluminum carbide that covers the surface the silicon particles. This can be prevented by coating the surface of the particles with a silicon oxide or nitride.

Synthesis Method for Aluminum Carbide

Aluminum carbide Al4C3 may be produced by combining directly two elements under high temperature. Mix 1 part heavy black smoke and 6 parts aluminum powder. Moisten the mixture with pine oil. Spread a thin layer of carbon on top. The crucible is covered with a cover and the asbestos fibers mixed with refractory dirt are smeared in all gaps. The mixture is then fired for 30 mins at a temperature no lower than 1200 after the crucible has been pre-dried in an oven. Higher temperatures can improve the reaction. After cooling, diluted hydrochloric solution (or an alkaline solution), under cooling, is used to remove any excess aluminum. After obtaining the aluminum carbide as a fine powder, it is washed to remove aluminum chloride with water. Alcohol is then used to quickly wash away the water. The product is then dried in a box set at a temperature between 80 and 90 degrees. The product contains an excessive amount of aluminum chloride.

Aluminum carbide itself is colorless. However, the products that are made using the above method can have different colors because of impurities. Calculated amounts of aluminum and soot are calcined using hydrogen. This produces a pure aluminum carbide without aluminum nitride. This calcination must be performed at 18001900°C for 23 hours. The obtained product is then ground, and again calcined above the temperature.

Tech Co., Ltd. () is an aluminum carbide manufacturer with 12 years' experience in research and product development. You can send us an inquiry if you're looking for high-quality aluminum carbide powder.