Advantages and applications of aluminum nitride

Aluminum nitride AlN melts at 2800°C and is stable at higher temperatures in an inert environment. It has excellent thermal conductivity and electrical insulation properties. Additionally, it has low dielectric constant and loss. This combination makes it a valuable advanced material for many applications, including optics and lighting, electronics, renewable energy, and other electronic devices.

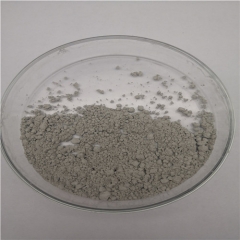

Aluminum nitride structure

Aluminum nitride AlN is a covalent bonding substance with a hexagonal crystal structure. The most common methods of preparing aluminum Nitride include direct nitridation (carbothermal reduction), high-energy ball milling and high-temperature self propagating synthesis. Chemical vapor deposition is another popular method.

The preparation method for aluminum nitride clays

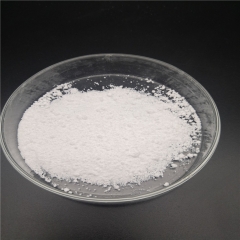

Aluminum nitride clays can be prepared in the same way as other ceramic materials. There are three main preparation methods: powder synthesis; molding; and sintering.

As the raw material, aluminum nitride is used to make the final ceramic product. Its purity, size, particles, oxygen content, and other impurities have a significant impact on the thermal conductivity, subsequent drying, and the forming of the final product. It is the outstanding performance of the final product. cornerstone. There are several ways to make aluminum nitride, including direct nitridation or carbothermic reduction, self propagating high-temperature synthesizing, chemical vapor deposition, and self-propagating.

Molding process for aluminum nitride dust

There are many ways to mold aluminum nitride for powder. These include traditional molding processes like molding, hot pressing and isostatic press. All of them are possible. All are applicable due to the high hydrophilicity aluminum nitride granules. To reduce the risk of aluminum oxide oxidation, avoid contact with water while molding. Although hot pressing and isostatic presses are capable of preparing high-performance bulk aluminium nitride materials, their high production costs and inefficientness cannot be met by the rising demand for aluminum substrates for electronics. This problem was solved by adopting the casting method to create aluminum nitride clay substrates. The aluminum nitride clays used in electronics manufacturing are also made using the tape casting process.

Aluminum Nitride Ceramics

Aluminum nitride ceramics are also used extensively as a substrate, electronic film material and as a coating for crucible or other refractory material. Aluminum nitride can also be used as a container to vacuum evaporation and the smelting metals.

Its numerous excellent properties make aluminum nitride a versatile material. It is a piezoelectric film and has been widely used. As the market develops, the applications of aluminum nitride-ceramic materials will expand. This is becoming more common.

Tech Co., Ltd. is an aluminum powder supplier. We have over 12 years of chemical products research and product development experience. We accept payments via Credit Card and Paypal. We will ship goods overseas via FedEx, DHL and by air or sea to our customers.

We can provide high-quality titanium diboride powder. Please contact us to send an inquiry.