What is Boron and its application

Boron - Preparation

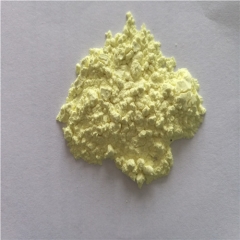

The sodium metaborate first obtained is by decomposing the magnesium borate solution with concentrated alkali, then crystallizing NaBO2 solution in strong alkali, making the solution dissolve in water, increasing the concentration, and finally concentrating the crystallization. Adjust the acidity of the sodium tetraborate solution with sulfuric to precipitate crystals of boric acids with low solubility. After heating, boric acid dehydrates to produce borontrioxide. Then, after drying, crude-boron is obtained through reducing B2O3 by magnesium or aluminium. After treating crude boron with hydrochloric, sodium hydroxide and hydrogen fluoride respectively, brown amorphous boran with a purity between 95-98% is obtained.

By hydrogen reduction, you can make the purest monomeric form of boron. You pass a mixture of hydrogen with borontribromide through a tantalum rod, heat it up to 1500K using an electric heater, and then reduce the borontribromide by hydrogen.

You can also obtain boron by heating magnesium or aluminum powder and reducing boron dioxide.

Use of boron for industrial purposes

Boron, a chemical raw-material mineral with a variety of uses, is used in a number of industries. It is primarily used to produce borax, boric acids, and boron as well as the elemental boron. It is widely used in metallurgy as well as building materials, machinery and electrical appliances. Chemicals, light-weight wool, nuclear industries, medicine, agriculture and other sectors. Important raw materials. Boron is used in more than 300 products. Glass, ceramics, detergents, and fertilizers for agriculture are some of the major uses.

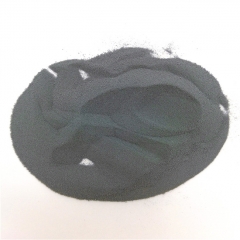

Elemental Boron is used in reducing agents, oxidizing agents, brominating agents, blend materials of organic synthesis and as an insulator for high voltage, high frequency electricity, plasma arcs, and transmission windows of radar.

Boron The boron element is found in trace amounts of alloys. When combined with plastic or aluminium alloy, it can be used to shield neutrons. Boron-containing additives improve sintering, which is important in the metal industry. The quality of ore can reduce the melting point and reduce the expansion. It also improves strength and hardness. Boron and its derivatives are also a cosolvent in metallurgical industries and a raw materials for smelting steel boron-iron boron. The addition of titanium boride or lithium boride to building materials and heat-resistant alloys can produce these compounds. Borates, borides, and other borates are essential components in enamel, ceramics, glass, and ceramics. They can be used to improve the surface finish and gloss of a product.

Boric acid

Zinc borate may be used to create fireproof fibers. It's a good fire retardant. It can also be used for bleaching and mordant dying. In fabric bleaching, sodium metaborate can be used. Boron compounds and paint desiccants can also be used to make soldering and wastewater treatment agents containing mercury in the paper industry.

Boron can be found as a trace in quartz. How to reduce boron to the minimum is the key in the purification of quartz sand. The presence boron lowers the melting point and decreases the number uses of the quartz crucible. This increases production costs of monocrystalline silica.

China has abundant boron-ore resources but boron-ore products cannot meet domestic construction needs. Domestic borax production was around 400,000 tons in 2007, imported boron-ore products were 648.700 tons. This is a high dependence on imports.

(aka. Technology Co. Ltd., a trusted global chemical supplier & manufacturer of super-high-quality chemicals & Nanomaterials with over 12 year's experience. Boron Powder produced by our company is of high purity and has a low impurity level. Please. Contact us if necessary.