About Aluminium oxide:

Aluminum oxide is an electrical insulator, it has a fairly high thermal conductivity to ceramic materials. The most common form of crystalline alumina is called corundum. Alumina can provide activated, super-activated, acidic, alkaline and neutral grades, and has flash grades, TLC, biomass purification, decolorization, dioxin analysis, PCB removal, pyrogen removal and biotechnology wide-pore forms. Oxide does not conduct electricity. However, certain oxides of perovskite structures have conductivity in the cathodes of solid oxide fuel cells and oxygen generation systems. They are compounds containing at least one oxygen anion and one metal cation. They are generally insoluble in aqueous solutions (water) and are very stable, so they can be used in ceramic structures, such as clay bowls for the production of advanced electronic devices, and lightweight structural components used in aerospace and electrochemical applications, such as fuel cells. Exhibits ionic conductivity. Metal oxides are basic acid anhydrides, so they can react with acids and strong reducing agents in redox reactions. Reactive chromatography grade alumina is used in lighting, photographic chromatography and various chromatographic separation techniques. Alumina is usually available in most quantities immediately. High purity, sub-micron and nanopowder forms can be considered. Alumina can also be made into particles, pellets, powders, sputtering targets, tablets and nano-powders. Provide typical and customized packaging, as well as other research, technical and safety (MSDS) data. Please contact us for the above delivery time and price information. Feel free to send an inquiry to get the latest price if you would like to buy Aluminum oxide in bulk.

How is Aluminium oxide produced?

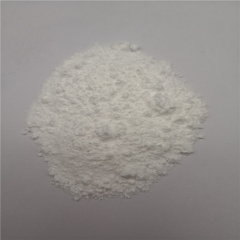

Aluminum oxide is produced by the bauxite process. The Bayer process is carried out in four steps. First, the bauxite is crushed, washed and dried, and then dissolved with caustic soda at high temperatures. Next, the mixture is filtered to remove impurities called "red mud" and discarded appropriately. The remaining alumina solution is transferred to a high tank called a settler. In the sedimentation tank, the hot solution begins to cool, and aluminum hydroxide seeds (very small particles) are added. The aluminum hydroxide seeds stimulate the precipitation of solid aluminum hydroxide crystals. Aluminum hydroxide precipitates at the bottom of the tank and is removed. Finally, all remaining caustic soda in the aluminum hydroxide is washed and heated to remove excess water. After this process, alumina (alumina) appears as a fine white powder. It looks a lot like sugar used in baking, but it is hard enough to scratch the glass plate.

Application of Aluminium oxide:

Most of the alumina produced is used to form aluminum metal. Oxygen usually reacts with metallic aluminum to catalyze corrosion. However, when combined with oxygen to form alumina, it forms a protective coating and prevents further oxidation. This increases the strength and makes the material less prone to deterioration. Alumina is mainly used as analytical reagents, dehydration of organic solvents, adsorbents, organic reaction catalysts, abrasives, polishing agents, raw materials for smelting aluminum, and refractory materials.

Industries that use alumina include:

Medical industry

Due to the hardness, biological inertness and chemical properties of alumina, it is used for hip replacement surgery prostheses, bionic implants, artificial eye substitutes, tissue reinforcement materials, crowns, abutments, bridges and other dental implants. The preferred material of the bearing. It is also used in laboratory equipment and tools such as crucibles, furnaces and other laboratory appliances.

Military and protective equipment

The strength and lightweight properties of alumina help to strengthen body armor, such as breastplates and armor for cars and airplanes, which is its largest market. Alumina is also used to synthesize sapphire bulletproof windows and bulletproof systems.

Electrical and electronic industry

Its high melting point and high boiling point, as well as its excellent heat resistance, make alumina an ideal material for high-temperature furnace insulators and electrical insulators. Alumina film is also a vital component in the microchip industry. Some of its other uses include spark plug insulators, micro-electric substrates and insulating heat sinks.

Performance of Aluminum Oxide Al2O3 Powder:

Aluminum oxide (aluminum oxide), chemical formula Al2O3. It is a high hardness compound with a melting point of 2054°C and a boiling point of 2980°C. It is an ion crystal that can be ionized at high temperatures and is commonly used in the manufacture of refractory materials. It is a white solid that is insoluble in water, odorless, tasteless, and extremely hard.

Technical Parameter of Aluminum Oxide Al2O3 Powder:

testing index | unit | Tr-D100 | Tr-D200 |

Chemical parameters | Al2O3 | % | ≥99.99 | ≥99.99 |

Fe | ppm | ≤8 | ≤8 |

Cr | ppm | ≤1 | ≤2 |

Mg | ppm | ≤1 | ≤2 |

Cu | ppm | ≤1 | ≤2 |

Ti | ppm | ≤1 | ≤2 |

Na | ppm | ≤30 | ≤30 |

Si | ppm | ≤20 | ≤20 |

Ca | ppm | ≤1 | ≤1 |

size parameter | D50 | μm | 0.5-30 | 1-30 |

Bulk density | — | g/m3 | 0.3-0.6 | 0.3-0.6 |

Specific surface area | — | m2/g | 2-10 | 10-20 |

Storage Condition of Aluminum Oxide Al2O3 Powder:

Aluminum Oxide Al2O3 Powder should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition, should avoid the heavy pressure, according to ordinary goods transportation.

Packing & Shipping of Aluminum Oxide Al2O3 Powder:

It is packed in double plastic bags inside, which can be filled with argon in a vacuum; it can be vacuumed and filled with argon for protection.

Aluminum Oxide Al2O3 Powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Aluminum Oxide Al2O3 Powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Aluminum Oxide Properties |

| Other Names | alumina, aluminum (III) oxide, aluminum trioxide, Al2O3 powder |

| CAS No. | 1344-28-1 |

| Compound Formula | Al2O3 |

| Molecular Weight | 101.96 |

| Appearance | White Powder |

| Melting Point | 2072 °C |

| Boiling Point | 2977 °C |

| Density | 3.95 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 101.948 g/mol |

| | |

| | |

Aluminum Oxide Health & Safety Information |

| Signal Word | N/A |

| Hazard Statements | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | NONH |

Inquiry us