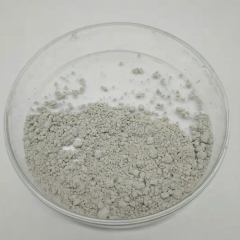

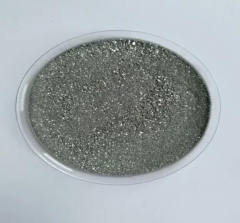

Lithium Carbide

Lithium carbide is a lithium rich chemical compound that is a potential cathode material for lithium ion batteries. The lithium carbide consists of a lithium atom bonding to a carbon triple bond.

There are two types of lithium carbide. One is an acetylide, which is formed by reacting lithium with acetylene. Another type is a carbonate, which is formed by reacting lithium with carbon.

Lithium carbide is a solid, non-flammable compound. It is also reactive and can be used as a cathode material in a lithium ion battery.

Lithium carbide has a P6/mmm phase. This is the same symmetry as the graphite intercalation compounds found in the lithium ion rechargeable battery art.

The chemical structure of lithium carbide is not well understood. However, it has been investigated using ab initio density functional theory (DFT) crystal structure searches. In these experiments, ground state lithium carbide crystal structures were searched for at 0 GPa and 40 GPa.

Stable crystal structures were identified in the lithium-carbon binary system. These structures suggest pathways to the development of novel car-bon materials.

Theoretical studies have shown that lithium-carbon binary systems possess a wide variety of chemical compounds. Although the exact nature of these compounds has yet to be fully understood, several types of thermodynamically stable phases have been identified. These include dimers, sheets, and nanoribbons.

Thermodynamically stable lithium-carbon binary systems also exhibit a range of interesting chemical bonding characteristics. The low electronic conductivity of these molecules is believed to be the reason for the potential gap between charge and discharge.

Inquiry us [contact-form-7 id="26" title="tongrun-form"]