Tantalum disilicide Uses

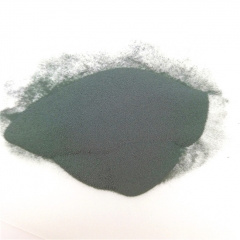

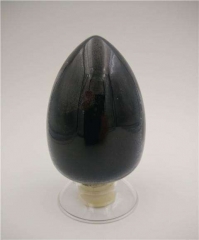

Tantalum disilicide chemical formula is TaSi2. It has exceptional properties such as high melting factor, reduced resistivity, rust resistance, high temperature oxidation resistance, and good compatibility with silicon, carbon as well as other matrix materials.

Tantalum disilicide Uses

Tantalum disilicide is primarily made use of in electrical heating components, high temperature level architectural elements, gateway products, connection circuits of incorporated circuits, heat oxidation resistance layers, cermets, ceramic matrix composites, aerospace, engines, as well as other fields.

Steel silicide

Tantalum disilicide is a sort of refractory metal silicide.

Metal silicide refers to the hard substance formed by change steel as well as silicon. Due to the big radius of silicon atoms, it can not form interstitial substances with change metals, so these difficult substances have secure chemical structure and excellent oxidation resistance.

Steel silicide has comparable electric conductivity, high temperature efficiency, oxidation resistance and compatibility with silicon incorporated circuit manufacturing process. Transition metal silicide can be utilized for low resistance gateway as well as internal electrical wiring, resistance get in touch with.

Tantalum silicide Production

The prep work techniques of tantalum silicide consist of combustion synthesis (CS) or self-propagating heat synthesis (SHS), and also arc melting.

Burning synthesis or self-propagating high temperature synthesis is a technique for the synthesis of intermetallic compounds by the exothermic response of elements/ substances. It has the benefits of straightforward tools, reduced energy consumption as well as brief synthesis time. Its primary drawbacks are quick response speed, difficult procedure control and also easy presence of assorted phases.

The burning synthesis of tantalum silicide requires pre-heating to start the response to recognize the synthesis, but there is a phase aside from disilicide.

Arc melting typically takes a very long time to co-opt, and also the loss of silicon triggered by volatilization in the melting procedure might cause the formation of some pollutant phases. Because of its jet temperature as much as 10000 ℃ and jet accelerate to 300-400m/ s, plasma splashing technology has the advantages of heat melting, fast solidification as well as near-net forming, as well as it is not limited by form or size, so it is simple to recognize its brief process forming, so it has progressively developed into a brand-new sort of components forming innovation, which has actually been utilized to prepare some components. Tantalum silicide powder is made right into mass product by plasma splashing modern technology, which calls for high pureness tantalum silicide powder as raw material. Consequently, how to acquire high pureness tantalum silicide powder (without contamination phase development) comes to be the secret.

Tantalum silicide Rate

The price is influenced by numerous aspects consisting of the supply and also need in the marketplace, sector fads, economic activity, market view, as well as unexpected events.

If you are seeking the most recent TaSi2 powder rate, you can send us your inquiry for a quote. (brad@ihpa.net)

Tantalum silicide Vendor

Innovation Co. Ltd. () is a trusted tantalum silicide producer and tantalum silicide supplier with over 12-year-experience. We ship our goods around the world.

If you are seeking top notch TaSi2 powder, please do not hesitate to contact us as well as send an inquiry. (brad@ihpa.net)