The Application of Natural Flake Graphite Powder

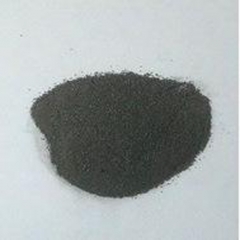

Flake graphite can be found in complete crystals or thin flakes. It has good physical and chemical properties and excellent thermal conductivity.

Natural Flake Graphite Application

RefractoryFlake graphite is used widely in advanced refractories in the metalurgical industry. Magnesia carbon bricks, crucibles, and others. Stabilizers in the military industry for pyrotechnics, desulfurization accelerators, pencil leads, and carbon brushes for industry.

After intensive processing flake graphite can be made into graphite oil, which can then be used in lubricants and mold release agents as well as wire drawing agents and conductive coatings. It can also produce expanded graphite which is used in flexible graphite products like flexible graphite seals, flexible graphite-composite products, and so on.

Coating

Flake graphite is used primarily as a functional filler for coatings.

Anti-corrosion material: The anti-rust primer is made of natural phosphorous flake Graphite and carbon Black, talcum Powder, and oil. It has good resistance to chemicals and solvents. Chemical pigments such zinc yellow can be added to the formulation to prevent rust.

Expandable graphite can be used as a fireproof material. This is a form of graphite interlaminar compound that has been produced by electrochemical or chemical treatment of natural graphite flake materials. Expandable graphite expands rapidly under heating (up to 300x), which suffocates a flame. It also generates expansions which can help isolate the flame or stop it from spreading. It is incombustible, flexible, strong, and has high surface energie.

Flake graphite may be used to make conductive coatings or as a carbon-based filler. Due to the large number of graphite flake added, the coating's performance and ease of application will be reduced. Therefore, it is necessary to improve graphite's conductivity and reduce the amount graphite flakes that are added.

This short-cut fiber material is a solvent-free thick films conductive coating with functional filleders. It has characteristics such as anti-corrosive medium penetration and low curing residue stress. It is also resistant to matrix deformation and cracking. The coating can be used for long-term static electricity transmission. The inner wall of crude oil storage tank's crude oil storage tanks can be coated with natural phosphorous flake graphite.

According to reports, electroless plating technology can be used to coat graphite dust with metals like nickel, silver, and copper. This allows for the preparation of composite conductive fillers. They are used in conductive coateds in an amount 30%. This not only improves conductivity, but also provides corrosion resistance.

Tech Co., Ltd. () is a professional Elemental powder Over 12 years of chemical products research and product development experience. We accept credit cards, T/T and Paypal payments. We will ship goods overseas via FedEx, DHL and by air or sea to our customers.

Feel free to contact me if you're looking for graphite powder with high quality. Get in touch Send an inquiry