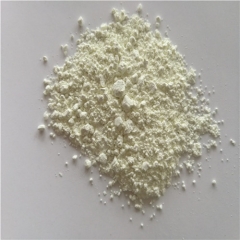

Water atomization is one of the important preparation methods for 3D printing metal powder

technology allows for 3D printing. Its most notable advantage is the ability to generate parts in any shape directly from computer graphics data, without any machining and molds. This greatly reduces the product development cycle while increasing productivity and reducing costs. Metal powder, the main raw material in 3D printing of metal components, has caught people's interest. 3D Printing Metal Powder is the most valuable and important part of 3D Printing Industry Chain of Metal Parts.

Metal powder preparation

The metal powder preparation processes can currently be divided into the following categories: reduction method (also known as a reduction process), electrolysis method (also known as a carbonyl decomposition technique), grinding method (also called atomization technique), etc. The preparation process determines the type of metal powder. In the powder metallurgy sector, powders produced by reduction, atomization, and electrolysis are the most commonly used raw materials. The atomization technique can be used to make alloy powder. A modern atomization procedure can also control powder shape. The development of atomization cavities has greatly improved the efficiency, and the atomization technique is gradually becoming the most popular method for producing powder. The atomization technique meets the specific requirements of 3D printed consumable metals powder. The atomization process is a way to mechanically reduce molten metal particles down to less than 150mm.

Water atomization

The water atomization process is one of the cheapest methods of production for atomized powder. The atomization media water is cheap, easily available and has excellent atomization. The domestic water atomization technique is used primarily to produce steel, matrix powders for diamond tools, prealloy powders for oil-bearing rollers, powders for hard-surface technology, and nickel and iron-based magnet powders. The specific heat of water being much greater than the gas's, it is possible that the metal droplets will solidify and become irregular during the atomization. Water will react with other metals or alloys that have a high level of activity. In addition, contact with the water during atomization will increase the amount of oxygen in the powder. This limits the use of water atomization for metal powders of high sphericity with low oxygen contents.

(aka. Technology Co. Ltd., a global leader in chemical material manufacturing and supply with over 12 year's experience in providing high-quality nanomaterials and chemicals. Our Metal Powder is of high purity with fine particles and low impurity levels. Contact us if you need to.