The Properties And Application of Molybdenum Carbide

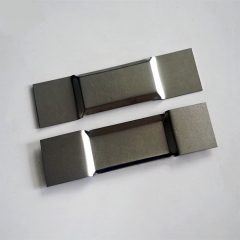

Molybdenum Carbide has the chemical formula MoC. Its molecular weight 107.95.

The material is known for its high melting and hardness points, thermal and mechanical stability and corrosion resistance.

Molybdenum Carbide has a hexagonal gray crystal. It has a high melting and hardness point, as well as good mechanical and thermal stability. The melting temperature is 2692degC. It is insoluble in water, lye and sulfuric acid.

1. Molybdenum Alloy

TZM is the alloy with the highest strength and most comprehensive properties. The United States uses TZM for turbine disks, which account for 15 percent of the total molybdenum. In my country, we produce no less than 22 types of molybdenum material. This includes TZM molybdenum. Early 1990s, the output of my country in molybdenum alloys and molybdenum was around 200 tons.

The TZM and TZC alloys offer superior mechanical properties to pure molybdenum. They are widely used for high-tech parts, such as molds, and structural components. In the early 20th century, my nation successfully produced them as thermally perforated seamless steel pipe plugs. The sintered molybdenum pipe plugs made using powder metallurgy can reduce the raw material consumption (50%) and increase the average service life 1.5 to 2.

The seamless tube of molybdenum and rhenium (containing 50% Re), has excellent high-performance, and can be used near its melting point. It can also be used to make the brackets, rings, grids, and other parts for thermowells or electron tube cathodes.

It is easier to work with molybdenum than tungsten. The plates, strips and foils can be used to make tubes, rods wires profiles etc. These are used to make electronic tubes (grids), electric light sources (support material), metal processing tool (die-casting dies, extrusion dies forging dies perforated plugs liquid metal screens), turbine discs etc. Used in many components.

2. Alloying components of steel

Molybdenum is an alloying metal that, when combined with nickel and chrome, can help reduce the embrittlement of alloy steels. The use of molybdenum in high-speed alloys to replace the tungsten is a leading solution for the shortage of tungsten. Molybdenum, according to calculations has twice the capacity of tungsten. The steel that contains 18% tungsten is replaced by steel that contains 9% molybdenum. Molybdenum's role in stainless steel is to enhance corrosion resistance, strength and weldability. You can see that molybdenum has a major role to play in the steel sector.

3. Other apps

Molybdenum exhibits a very low vapour pressure when working at the pressure and temperature of the vacuum oven. Molybdenum is the material that causes the least contamination to the materials and workpieces inside the vacuum furnace.

Due to its high strength, molybdenum makes the ideal electrode in glass manufacturing. It is also the most suitable processing equipment and electrode during rapid heating. Because molybdenum is chemically incompatible with most glass components, it will not produce harmful color changes due to the small amount of molybdenum that may be dissolved in a glass melting tank. As a heating electrode in a glass melt furnace, it can last up to 3 or 5 years.

4. Emerging applications

Molybdenum diilicide (MoSi2) is a composite material that can be used to overcome the low ductility, high oxidation and low ductility problems.

Molybdenum Carbide has excellent properties in terms of electrical, mechanical, and thermal properties. It is widely used as a composite material in advanced composites.

Tech Co., Ltd. () is an expert in Molybdenum Carbide, and has over 12 years' experience in research and product development. You can contact us to send an inquiry if you are interested in high quality Molybdenum Carbide.