Processing technology and heat treatment of copper-nickel alloy custom metal plates

Copper-nickel alloy handling technology

Creating: Copper-nickel alloys can be processed through forging processes. At an ideal temperature level, the alloy billet heated to a strong solution state is placed in the mold and mildew, and stress is applied to build parts of the wanted shape. Forging boosts the strength and thickness of the alloy and improves its mechanical homes.

Warm Rolling: Copper-nickel alloys can be processed with the hot rolling process. The alloy billet heated up to a strong option state is put into the rolling mill and rolled with numerous passes to slowly decrease the cross-sectional size to obtain plates or bars of the required shape and size. Warm rolling can improve the toughness and sturdiness of the alloy and obtain a consistent business structure.

Cold Rolling: Copper-nickel alloys can also be processed through the chilly rolling procedure. The alloy plates or bars are put into the cool rolling mill and go through numerous chilly rolling contortions to acquire the called for sizes and shape. Cold rolling can even more boost the strength and firmness of the alloy while raising corrosion resistance.

Extrusion: Copper-nickel alloys can be refined through the extrusion procedure. The alloy billet heated up to a strong solution state is put into an extruder, and stress is put on extrude the alloy billet into the desired shape and size. Extrusion can boost the density and mechanical properties of the alloy and obtain a consistent organizational structure.

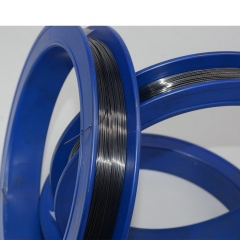

Drawing: Copper-nickel alloys can be refined via an attracting procedure. After the alloy billet is heated to a strong remedy state, it is formed into the called for shape and size via stretching and deformation. Stretching rises the stamina and sturdiness of the alloy and improves its product residential properties.

(Copper nickel alloy )

Warm therapy properties of copper-nickel alloy

Strong remedy therapy: by heating to an appropriate temperature level and afterwards quickly cooling down, the alloy reaches a consistent strong solution state. Solid option treatment can get rid of the rainfall stage and intergranular phase in the alloy and boost the plasticity and forgeability of the alloy.

Aging therapy: After option therapy, the alloy is heated up to an appropriate temperature level and preserved for a long time before cooling down. Aging therapy can present brand-new rainfall phases, further boost the toughness and firmness of the alloy, and rise deterioration resistance.

Cold work solidifying: The alloy is plastically flawed with chilly working (such as cold rolling, cold extrusion, etc) and after that aged. Cold work hardening can significantly boost an alloy's toughness and firmness and boost its sturdiness and corrosion resistance.

Stablizing: For parts that have actually been used for a long time, stabilization can be executed to get rid of tension and residual contortion. Stabilization treatment entails warming the part to a reduced temperature and keeping it for time to kick back the tension and readjust the structure of the alloy.

(Copper nickel alloy)

About MetalCladBuilders

Metalcladbuilders is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality metals and metal alloy. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Metalinchina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for custom metal plates, please send an email to: nanotrun@yahoo.com

Inquiry us [contact-form-7 id="26" title="tongrun-form"]