Scandium Aluminum Alloy Al-Sc Alloy

About Scandium Aluminum Alloy Al-Sc Alloy:

Al-Sc alloy is a kind of high-performance aluminum alloy. There are several ways to make an aluminum alloy with high performance. Microalloying hardening and toughening is the frontier field of research on high-performance aluminum alloy in recent 20 years. Scandium aluminum alloy is a successful combination of scandium and aluminum metal. Scandium is a silvery-white transition metal and is commonly listed as a rare earth element (REE) along with yttrium (Y) and the 15 lanthanides (La) elements. The alloying of scandium into an aluminum can increase the strength and desirable properties of aluminum. The addition of scandium restricts the excessive growth of grains in the heat-affected zone of aluminum welds. Orachemicals is a trusted global Scandium Aluminum Alloy Al-Sc Alloy supplier. Feel free to send an inquiry about the latest price of Al-Sc Alloy at any time.

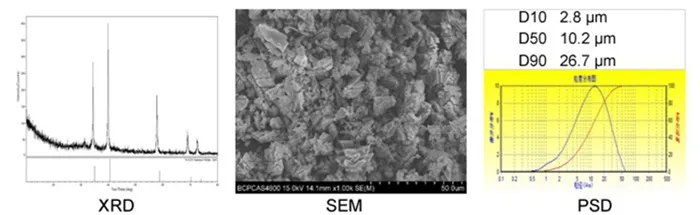

Product Performance of Scandium Aluminum Alloy Al-Sc Alloy :

Aluminum scandium intermediate alloy is a high-performance aluminum alloy, which can not only significantly refine the as-cast alloy grains, increase the recrystallization temperature to improve the strength and toughness of the aluminum alloy, but also significantly improve the weldability and resistance of the aluminum alloy Thermal, corrosion resistance, thermal stability and resistance to neutron radiation damage.

How is Scandium Aluminum Alloy Al-Sc Alloy Produced?

The preparation of the master alloy is the key to the production of Al-Sc alloy. The preparation method is as follows:

Preparation of anhydrous scandium chloride molten salt

1. Vacuum dehydration

Dissolve SC2O3 in hydrochloric acid, and mix SC2O3: NaCl: KCl: NH4Cl in proportion. Evaporation, vacuum removal.

2.Dehydrate at medium temperature

The molten salt after vacuum dehydration is heated under the protection of argon to make molten salt of ScCl3·NaCl·KCl, namely, anhydrous scandium chloride.

Preparation of Al-Mg-Sc master alloy

Industrial pure aluminum and industrial pure magnesium, ampere proportional heating melting. Adding SCCl3 ·NaCl·KCl molten salt, and specific additives, smelting, casting, aluminum, magnesium and scandium master alloy.

Applications of Scandium Aluminum Alloy Al-Sc Alloy:

Scandium aluminum alloys are used in small aerospace industry components. The common scandium content is 2%. The addition of scandium restricts the excessive growth of grains in the heat-affected zone of aluminum welds. Scandium can significantly increase the strength and decrease the grain size. The SC-Al alloy is also used in some sports equipment, including baseball bats, lacrosse sticks, and bicycle frames and related parts.

Aluminum can be made stronger by adding scandium

Scandium aluminum alloy has better welding property

The grain structure remains intact during the forming and extrusion process

When combined with zirconium, it increases with temperature.

Adding a small amount of scandium to the aluminum alloy can promote grain refinement and increase the recrystallization temperature from 250℃ to 280℃. Scandium is a strong grain refiner of aluminum alloy and an effective recrystallization inhibitor. It has a significant effect on the microstructure and properties of the alloy, and greatly improves the strength, hardness, weldability and corrosion resistance of the alloy.

Scandium has a good dispersive strengthening effect on aluminum and maintains a stable non-recrystallized structure under hot working or annealing conditions.

The inhibition effect of scandium on recrystallization can eliminate the recrystallization structure in the heat-affected zone of the weld. The subcrystalline structure of the matrix can be transferred directly to the as-cast structure of the weld seam, which makes the welded joint of an aluminum alloy containing scandium have higher strength and corrosion performance.

The effect of scandium on the corrosion resistance of the aluminum alloy is also related to the refinement of grain and the inhibition of the recrystallization process. The addition of scandium can also make the aluminum alloy have good superplasticity. The elongation of an aluminum alloy containing about 0.5% scandium can reach 1100% after superplastic treatment.

An aluminum alloy containing scandium has become the most competitive high-performance aluminum alloy structure material after Al-Li alloy. The application prospect of scandium aluminum alloy in shipbuilding, aerospace, rocket missile, nuclear energy and other high-tech fields is very broad. By adding a small amount of scandium, a series of new high-performance aluminum alloy materials, such as ultra-high strength and high toughness aluminum alloy and high strength and corrosion-resistant aluminum alloy, can be developed on the basis of the existing aluminum alloy.

Storage Condition of Scandium Aluminum Alloy Al-Sc Alloy :

The damp reunion will affect Al-Sc alloy dispersion performance and using effects, therefore, scandium aluminum alloy should be sealed in vacuum packing and stored in a cool and dry room, the scandium aluminum alloy can not be exposure to air. In addition, the Al-Sc alloy should be avoided under stress.

Packing & Shipping of Scandium Aluminum Alloy Al-Sc Alloy :

We have kinds of packages according to your scandium aluminum alloy quantity.

Scandium aluminum alloy Al-Sc alloy packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Scandium aluminum alloy Al-Sc alloy shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Scandium Alumium Alloy Properties | |

| Other Names | AlSc, ScAl, Sc:Al, scandium aluminum, Sc-Al Powder |

| CAS No. | 113413-85-7 |

| Compound Formula | Sc-Al |

| Molecular Weight | 71.93 |

| Appearance | Metallic solid |

| Melting Point | 655℃ |

| Boiling Point | N/A |

| Density | 2.7 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 71.937451 |

Scandium Alumium Alloy Health & Safety Information | |

| Signal Word | Danger |

| Hazard Statements | H228-H261 |

| Hazard Codes | F |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | UN3077 9/PG III |