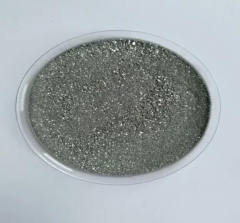

Introduction to Spherical Quartz siO2 Powder

Spherical powder of quartz

Also known as

Spherical silicon powder

Amorphous quartz is a powder of amorphous silica. The individual particles are spherical. It is white in color, with uniform particle sizes, good transparency, chemical and thermal stability, safety, insoluble in water, and has high levels of safety.

Quartz powder in spheres

It is used to make large-scale integrated circuit packaging. It is also used for high-tech applications such as aerospace, fine chemicals and daily cosmetics.

Physicochemical properties of Spherical Quartz SiO2 powder

Quartz powder in spheres

It offers the benefits of a smooth surface and large specific area.

First of all, the powder is fluid and can be stirred with resin to form an even film. The resin can be added in small amounts, but the amount of quartz powder used for filling is substantial. The mass fraction can go up to 90.5%. The more quartz powder added to the mix, the lower its thermal conductivity. Additionally, the less thermal expansion coefficient the plastic sealing material has, the higher the performance of electronic components.

Second, the stress in spherical granules is less than that in angular granules. Also, the strength and stress concentrations of plastic sealants made from spherical Quartz powder are the lowest and highest. The yield is high when integrated circuit chips are encapsulated in spherical-powder plastic packing material. This makes it difficult to cause mechanical damage during transportation, installation and use.

Third, because the surface of the powder is smooth, it has a low friction coefficient, wear is minimal and molds can last for more than one time.

|

Spherical Quartz SiO2 Powder Properties

|

|

Other names

|

fused quartz, spherical quartz, spherical SiO2, silica

|

|

CAS No.

|

7631-86-9

|

|

Formula compound

|

SiO2

|

|

Molecular Weight

|

60.09

|

|

Appearance

|

white powder

|

|

Melting Point

|

1,600deg C (2,912deg F)

|

|

Boiling Point

|

2,230deg C (4,046deg F)

|

|

Density

|

2533kg/m3

|

|

Solubility of H2O

|

Insoluble

|

|

Exact Mass

|

59.9668

|

Spherical Quartz Powder Spherical SiO2

Spherical Quartz SiO2 Pulverization Methods

Flame melting method, plasma heating furnace technique, chemical synthesis and hydrolysis are the most common methods to prepare spherical powder.

1.

Flame melting method

Ball formation is achieved by using a high temperature flame gun that emits 1600-2000 high temperatures flame. The powder then absorbs heat from the flame and becomes molten. This heat is transferred to the powder inside, which is completely molten. Surface tension causes the object to always move to the stable condition, while the spherical shape is the most stable, in order to accomplish the product's purpose.

2.

Plasma heating furnace method

Hot plasma (also known as local thermodynamic balance plasma) is characterized by the presence of a local electron (Te), an ion(Ti), or a gas (Tg). These features are nearly identical. The thermal plasma category includes arc plasma, high-frequency and induction plasma.

High-frequency plasma melting is an efficient method of producing spherical quartz. The method uses moderate temperatures, stable control, high yield, and a high yield to achieve a higher level of spheroidization. Similar to the flame melting method, its principle and procedure are the same. The only difference is that the plasma generator is switched from a high-temperature heat source.

3.

Chemical synthesis

At a specific temperature, silica sol was treated with ammonia/ammonium bicarbose in order to obtain spherical gel. The gel was then treated with acid to produce hydrated spherical Silica. Finally, it was refined and heat-treated to obtain spherical Silica powder. It has low uranium and is easy for people to agglomerate.

4.

Hydrolysis is a method

: Add the liquid SiCl4 and deionized water with different dipersants at constant speed. The hydrolysate can then be stirred with a quartz rod at high speed. After washing, drying, and filtering, the hydrolysate has been dried, dehydrated to a constant weight in an oven at 100-200 degrees Celsius, and then transferred to the high temperature sintering furnace. High-temperature dehydroxylation at different temperatures can result in high-purity spherical quartz crystal powder.

Spherical Quartz SiO2 Pulverized for Applications

Quartz powder is a high-performance substrate or packaging material that can be used in large-scale and very large-scale integrated Circuits.

Spherical quartz powder is also widely used in electronic paint, electronic ink, optical fibre, high grade precision ceramic manufacturing and optical devices.

Main Supplier of Spherical Quarried SiO2 Powder

Technology Co. Ltd. is a trusted global supplier of chemical material and manufacturer. They have over 12 years experience in producing super high-quality chemicals, Nanomaterials, such as silicon powder.

High-quality products are what you want

Powdered SiO2 from spherical Quartz

Please feel free and contact us to send an inquiry. (brad@ihpa.net)