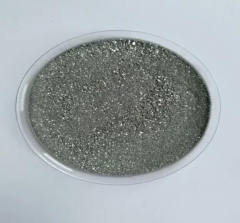

Aluminium Granules Supplier

aluminium granules supplier provides a wide range of aluminium granules. The granules are used in various applications such as building and construction, aerospace and defence, electronics, automotive, and chemical industry.

Aluminum granules are available in different forms such as atomized, flake, paste and pigment powder. They are a reactive and flammable material that undergoes exothermic reactions when it gets oxidized.

These granules are widely used in various industrial applications as they are lightweight and corrosion-resistant. They also increase the lifespan of the products that use them.

Currently, air atomization technology is the most popular method for manufacturing aluminium powder. This is because the process requires less energy, and can also be done in a controlled environment.

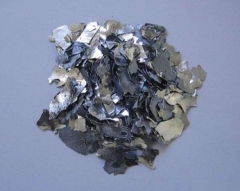

The other major process for producing the aluminium granules is casting. This is a process that involves melting the aluminium and then blowing it in air or vacuum. The granules are then cast in sand and then sieved off.

Centaur is an automated metal casting system which can be used to produce high quality aluminium granules. The system works around a water cooled rotating casting table that pours molten aluminium in droplets from specially designed moulds.

EC21 is the world’s largest global B2B marketplace that helps you find buyers from all over the world for your products and services. Post your buying leads for free here and receive daily enquiries from worldwide buyers.

American Elements produces a full line of high purity Aluminum granules and other grades. They are ideal for a variety of high purity applications such as semiconductors, coating liquids, and lens monomers. They are also a great choice for aluminum based solutions and organometallics.