Properties And Application of Titanium Carbide Based Cermet

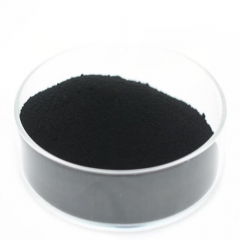

Titanium carbide properties:

Titanium carbide This crystal is iron grey with a metallic shine. It is a metal-like substance with similar properties: high melting, boiling and hardness points. Its thermal conductivity, electrical conductivity, and hardness are second only to that of diamond. It is superconductive at low temperatures. This substance can be used to make cermets as well as heat-resistant metals, antiwear materials, high temperature radiation materials and other high temperature vacuum devices.Titanium Carbide Based Cermet Properties:

As a typical transition-metal carbide, titanium carbide is intrinsically brittle, and so cannot be used for engineering components. As a result, it is often used to reinforce composite materials and as a material coating. Attention and application, as in the case of cermets based on titanium carbide.Titanium carbide based cermet (also known as cermet) is a heterogeneous material made of metal or alloy phase TiC. It combines high strength, high toughness, wear resistance high temperature resistance oxidation resistant and chemical stability ceramics as well as metal.

Application and Use of Titanium Carbide Based Ceramic:

1. Cutting metal tools The new titanium-carbide-based cermet tool material has been developing rapidly over the past few years. It offers a very high level of performance, and the wear resistance is higher than normal cemented carbide when cut under identical conditions. Wear resistance in high-speed cuts is 5 to 8 time higher than cemented carbide (YT14 and 15) compared to YT14. Titan carbide-based blades are now being made in various shapes and sizes, and used in precision drilling holes, "turning instead" of grinding, and other finishing fields.2.Aerospace industry: This TiC/Cu cermet, prepared using a high-temperature sintered infiltration framework process, has excellent ablation resistance. It can be used for the lining of rocket throats and as a guard plate material.

3.Others: This metal-based ceramic lining can be used for anti-corrosion pipelines for transporting petroleum, chemical and semi-products. Also, it can be used for anti-wear pipelines for mines and beneficiation plants, as well as slurry pipelines. The lining is also suitable for use in water pipes with muddy waters...

Tech Co., Ltd. is a professional Titanium Carbide We have over 12 year experience in research and development of chemical products. You can contact us for Titanium Carbide. Contact us Send an inquiry.