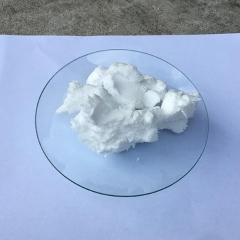

What is Tin disulfide?

Tin disulfide dissolves in hot alkali solution or aqua regia. It can also react with ammonium-sulfide to disperse.

How to prepare Tin Disulfide

Tin disulfide is made by mixing tin and sulfur with iodine. This reaction needs heating.

Sn + 2 SnS2

Another option is to pass hydrogen sulfuride into the Tin (IV) salt, or Tin (IV), salt solution and precipitate.

Electrochemical behaviour of multi-walled Carbon Nanotubes containing Tin Disulfide as Negative Electrode of Lithium Ion Battery

Multi-walled carbon-nanotube-confined metal-tin nanostructures were prepared using the direct current arc Plasma method. Brad@ihpa.net was then used as a precursor in methane, and finally brad@ihpa.net was obtained by the sulfurization process. Raman, Xray diffraction, and transmission electron microscopy were used to characterize the material. The length of the multi-walled, carbon nanotubes measured approximately 400nm. The surface carbon layer was well crystallized and the carbon layer thickness was around 10 nm. Sn brad@ihpa.net Nanostructures are used as anode material in lithium-ion battery. They show a good electrochemical performance. The first charge-discharge Coulomb efficiency of 71% is achieved, and after 50 cycles the capacity maintains 703?mAh?g-1. Brad@ihpa.net Nanostructured Electrodes have high-capacity properties due to the fact that different active materials provide different reactions platforms.

Study on electrochemical performance of tin disulfide/single-walled carbon nanotube composite material used as anode material for lithium-ion battery

The simple solvothermal process allowed for the creation of a new composite material consisting of SnS2 (SWCNTs), and single-walled, carbon nanotubes (SWCNTs). It has good electrochemical properties after being applied to the battery's negative electrode. It maintains a specific capacity of 515 mAh/g even at high current density (1 A/g), after 100 cycles. To compare, we used the exact same method to synthesize one SnS2 materials and performed electrochemical tests. The SnS2 materials have a relatively high specific capacity but a poor cycle performance and decays rapidly after only 20 cycles. This composite material is superior in lithium-ion batteries because of its synergy with SnS2 (and SWCNTs).

Tin disulfide Supplier

(aka. Technology Co. Ltd. (aka. Our company is currently working on a number of materials. Our Tin diulfide has high purity, fine particle sizes, and very low impurity. To get the current price of Tin diulfide, please send us an e-mail or click on the required products to send an enquiry.