What is Aluminum Diboride AlB2 Powder?

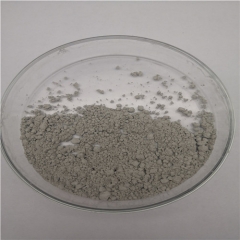

Aluminum diboride This is made from a mixture of fine powdered aluminum and boron, and then reacting with heat. It is one the two compounds of aluminum or boron, AlB12 being the other. They are often called aluminum boride.

Aluminum boride can be dangerous because it reacts to acid and hydrogen to make toxic gases. Aluminum boride can react with hydrochloric Acid to release borane and aluminum cyanide.

Aluminum Diboride Structures AlB2

The structure aluminum boride Similar to the structure of metal interdides, it is dependent mainly on the crystal structures of aluminum and boron. AlB2, AlB4, AlB12, and AlB12 are the aluminum borides. AlB2 is formed when two elements over 600 react to form the diboride AlB2. It is a layered structure that Al atoms directly overlap. A, A and B atoms are filling the triangular column created by the direct overlap Alatoms. This is the boron layer, which is located between the aluminum layers. The graphite-like structure of the boron layer is also similar. The hexagonal network connects the boron molecules. Each Batom is approximately 0.173nm distant from the other B atoms. Additionally, six Al atoms connect to B. These six Al atoms occupy the apex in the triangular column. Dilute hydrochloric Acid can dissolve AlB2 to make a reductive mixture that may contain HB (OH)+. AlB2 is not soluble in dilute sulfuric acids, but it is soluble in nitric. AlB2 was able to decompose AlB12 at 920

| Aluminum Diboride AlB2 Properties | |

| Other names | aluminum boride, aluminum diboride, AIB2 |

| CAS No. | 12041-50-8 |

| Formula compound | AlB2 |

| Molecular Weight | 48.604 |

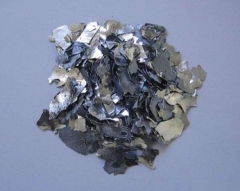

| Appearance | Solid copper-red |

| Melting Point | 920degC |

| Boiling Point | N/A |

| Density | 3.19g/cm3 |

| Solubility of H2O | Insoluble |

| Exact Mass | 49 |

Physicochemical properties and applications of aluminum diboride powder AlB2

AlB2 single crystal displays metallic conductivity along an alignment parallel to the hexagonal basis plane. Boron - Aluminum composite aluminum, aluminum alloy reinforced by boron fibr or protective coating of boron fibr. The volume content for boron fiber ranges from 45% to 55%. It has high specific gravity and excellent mechanical properties. The longitudinal tensile and elastic strength of the unidirectionally strengthened boron/aluminum composite vary depending on the material and process. The specific strengths and longitudinal specific elastic module are approximately 35 and 34 respectively, depending on the process and material. It exhibits good fatigue resistance and high strength below 400.

It was used for fan blades in turbojet engines as well as aerospace and structural parts. For manufacturing plate, profile, or more complicated shapes, hot pressing diffusion bonds is used. Continuous casting is also an option to produce different profiles.

Aluminum Boride is used in ceramics as well medical equipment, nuclear energy and refractory ceramics.

Main supplier of aluminum diboride alB2 powder

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. We have more than 12 years experience in producing super-high-quality chemicals.

High-quality products are what you want Aluminum Diboride AlB2 Powder Please feel free and contact us to send us an inquiry. (brad@ihpa.net)