The Applications of Hafnium Disilicide Powder

Hafnium Silicide is a silica of transition metals, which can also be used as an intermetallic compound.

The key features of Hafnium Disilicide Pulver

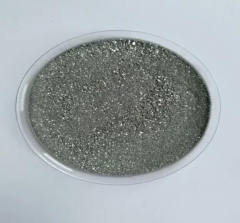

Hafnium silicide, HfSi2 dust (CAS 12401-56-08) has high melting points, high corrosion resistances, high oxidation resistants, and good electrical conductivity.

The applications Hafnium Disilicide Pulver

1. Prepare an organic electronic luminescence device. It includes an anode and a light-emitting coating, as well as a cathode. The packaging cover protects the light-emitting layers and the cathode of the anode. The packaging cover includes a silicon oxide layer and a barrier layers formed on the silicon carbonitride. The above-mentioned organic electronluminescent device has a very long life span. The invention provides a method to prepare the organic electrodeluminescent device.

2. Preparation of a silicone-germanium alloy-based thermoelectric device. The silicon–germanium alloy-based thermostatic element is composed of an electro layer, a silicon–germanium thermoelectric layer, as well as a barrier layer. This barrier layer is made up of silicides and silicon nitride. The silicon-germanium-alloy-based thermoelectric element provided has an excellent combination of interfaces. There are no cracks or visible diffusion phenomena at the interface. It can also withstand long-term high temperatures accelerated tests. Additionally, the provided preparation process has the advantages of being simple, reliable and low-cost, without the need for special equipment. It is suitable for large scale production.

3. A high temperature, oxidation resistant ceramic composite coating can be prepared. The composition of the composite film is as follows: the coating is composed of intermetallic compound, refractory carbide, and refractory metal. The thickness of the coating ranges from 10 to 50 millimeters. The refractory metallic is one or many of molybdenum and tantalum as well as zirconium, zirconium, and hafnium. The intermetallic compounds are composed of one or two of molybdenum and tantalum silicides and zirconium carbides. The crystal structure of the coating is made up of non-composition of crystalline or polycrystalline nanoparticles.

| Hafnium Silicide HFSi2 Powder Properties | |

| Other Titles | hafnium disilicide, hfSi2 |

| No. | 12401-56-8 |

| Combination Formula | HfSi2 |

| Molecular Weight | 234.66 |

| Appearance | Powder |

| Melting Point | N/A |

| Solubility of in water | N/A |

| Density | 7.6 g/cm3 |

| Purity | 99.00% |

| Particle size | 5-10um |

| Boling Point | N/A |

| Specific heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Modulus | N/A |

| Exact | 235.900402 |

| Monoisotopic | 235.900402 |

Tech Co., Ltd. () is a professional silicide paste Over 12 years' experience in chemical products development and research. We accept credit cards, T/T and West Union payments. We will ship goods overseas via FedEx, DHL and by air or sea to our customers.

You can find high-quality powdered boron carbide here Please contact us Send an inquiry