What is Magnesium Nitride?

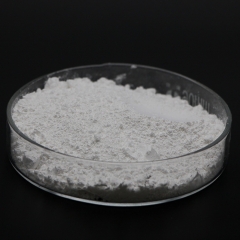

Magnesium nitride with the chemical formula Mg3N2 is an inorganic compound of magnesium and nitrogen..At room temperature and pressure, it is a green-yellow powder. Magnesium nitride is an inorganic compound composed of nitrogen and magnesium, with a molecular formula of Mg3N2 and a molecular weight of 100.9494. Belongs to the cubic crystal system. Magnesium nitride, like many metal nitrides, reacts with water to produce ammonia. To prepare magnesium nitride, the magnesium belt can be burned in nitrogen. Often used as a catalyst.

Technique Specifications of Magnesium nitride

| Synonym(s): | Trimagnesium dinitride |

| Linear Formula: | Mg3N2 |

| CAS Number: | 12057-71-5 |

| Molecular Weight: | 100.93 |

| EC Number: | 235-022-1 |

| MDL number: | MFCD00016205 |

| PubChem Substance ID: | 24865976 |

| NACRES: | NA.23 |

Mg has 2 valence electrons and loses these 2 valence electrons to form the Mg2+ ion. It gains 3 valence electrons to form N3− ion. To balance charges, 3 Mg2+ ions combine with two N3− ions to form Mg3N2.

Magnesium nitride is soluble in acid, slightly soluble in ethanol and ether. Magnesium nitride, like many metal nitrides, reacts with water to produce ammonia. Reacts with acids or water-containing non-metal oxides to produce ammonium and magnesium salts. Because magnesium nitride is easily combined with water (H2O) to decompose, it needs to be stored in a vacuum-sealed, waterproof and moisture-proof. Orachemicals is a trusted global Magnesium Nitride supplier. Feel free to send an inquiry about the latest price of Magnesium Nitride at any time. Magnesium nitride is slightly harmful to water bodies. Do not expose undiluted or large amounts of products to groundwater, waterways or sewage systems, and do not discharge materials into the surrounding environment without permission.

Like many metal nitrides, magnesium nitride reacts with water to generate magnesium hydroxide and ammonia gas.

Mg3N2(s)+ 6 H2O(l)→3 Mg(OH)2(aq)+ 2 NH3(g)

In fact, when magnesium is burned in the air, in addition to the main product magnesium oxide, some magnesium nitride will be formed.

The thermal decomposition of magnesium nitride produces magnesium and nitrogen (at 700-1500°C). How is Mg3N2 formed? Mg has 2 valence electrons and loses these 2 valence electrons to form the Mg2+ ion. It gains 3 valence electrons to form N3− ion. To balance charges, 3 Mg2+ ions combine with two N3− ions to form Mg3N2.

Product Performance of Magnesium Nitride Mg3N2 powder:

Magnesium nitride has a wide direct bandgap, strong atomic bonds, high thermal conductivity, good chemical stability

(almost no acid corrosion) and other properties and strong anti-radiation ability in optoelectronics, high temperature and

high power devices and high-Frequency microwave device applications have a broad prospect.

Technical Parameter of Magnesium Nitride Mg3N2 powder:

| Product Name | MF | Purity | Particle Size | Melting Point | Density | Color |

| magnesium nitride | Mg3N2 | 99% | 5-10um | 800℃ | 2.712g/ml | yellow-brown |

Chemical Composition of Magnesium Nitride Mg3N2 powder:

| Mg3N2 | N | Mg | Si | O | C | Fe |

| 99% | 11% | balance | 0.002% | 0.2% | 0.05% | 0.15% |

How is Magnesium Nitride Mg3N2 Powder produced?

To prepare magnesium nitride, the magnesium belt can be burned in nitrogen.

What do magnesium and nitrogen make? Solid magnesium reacts with nitrogen gas to form solid magnesium nitride.

In the above reaction, if the nitrogen is not pure, it is easy to produce products containing magnesium oxide. The method of reaction in dry NH3 gas is better.

Place the magnesium scraps in a porcelain boat or a sintered magnesia boat. The boat is installed in a porcelain tube. One end of the porcelain tube is connected to a T-shaped tube. One end of the T-shaped tube can be filled with dry ammonia gas and the other end can be filled with nitrogen. The end of the porcelain tube is connected to a U-shaped tube, and the tube is filled with desiccant, half of which is small flakes of CaO, and the other half is small flakes of KOH. The gas discharged from the reaction tube is absorbed by the absorption device, which is two conical flasks containing dilute sulfuric acid. In order to prevent back suction, do not insert the tube of the first absorption bottle below the surface of the dilute sulfuric acid.

Pour dry NH3 and N2 into the porcelain tube until the second absorption bottle no longer emits bubbles, indicating that the air in the porcelain tube has been purged. Raise the temperature to 800~850℃, heat the magnesium powder for 4 hours, the magnesium powder becomes hot, marking the beginning of the reaction, and at the same time, H2 must be produced. During the reaction, the pressure of NH3 should be greater than the outside atmospheric pressure to avoid sucking back. When the reaction is over, turn off NH3, keep the original temperature and continue to pass N2 for 1.5h to remove NH3·Mg3N2 adsorbed on Mg3N2, which is very deliquescent and must be stored in a dry container. If the magnesium belt is burned in the air, in addition to magnesium oxide, some magnesium nitride will also be produced.

Applications of Magnesium Nitride Mg3N2 Powder:

Magnesium nitride (Mg3N2) powder is a well-known solid catalyst and is used as an additive in a range of applications, including fabricating special alloys and ceramics, catalyzing polymer cross-linking reactions and hydrogen storage materials.

What is magnesium nitride used for?

1. Magnesium nitride is used as a catalyst when preparing nitrides of other elements with high hardness, high thermal conductivity, corrosion resistance, wear-resistance and high-temperature resistance. When the cubic boron nitride was successfully synthesized for the first time, the catalyst used was magnesium nitride;

2. Magnesium nitride additives used in high-strength steel smelting. Magnesium nitride (Mg3N2) replaces desulfurized magnesium in construction steel smelting, which is beneficial to improve the density, strength, tensile strength and endurance of steel. In addition, the use of magnesium nitride (Mg3N2) for desulfurization can reduce other additives in an appropriate amount, thereby helping to reduce the production cost of construction steel;

3. Preparation of special ceramic materials;

4. Foaming agent for manufacturing special alloys;

5. Magnesium nitride used to manufacture special glass;

6. Catalytic polymer cross-linking;

7. Recycling of nuclear waste;

8. Magnesium nitride used as a catalyst material for synthetic diamond synthesis and cubic boron nitride.

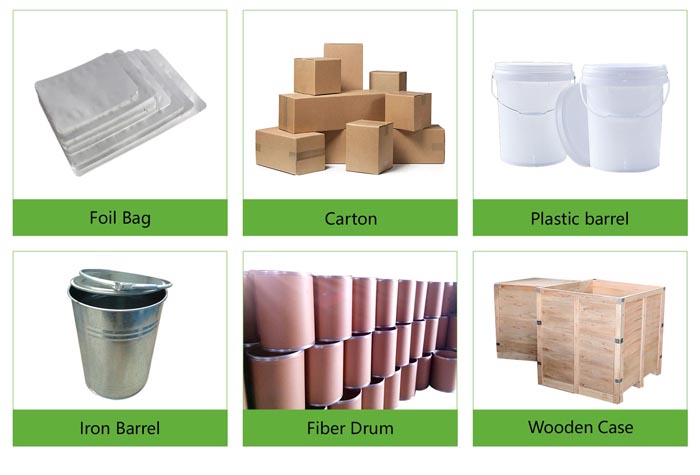

Packing & Shipping of Magnesium Nitride Mg3N2 powder:

We have many different kinds of packing which depend on the magnesium nitride Mg3N2 powder quantity.

Magnesium nitride Mg3N2 powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Magnesium nitride Mg3N2 powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Magnesium Nitride Properties |

| Other Names | trimagnesium dinitride, Mg3N2 powder |

| CAS No. | 12057-71-5 |

| Compound Formula | Mg3N2 |

| Molecular Weight | 100.93 |

| Appearance | Yellow to Brown Powder |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | 2.71 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 99.961273 |

| | |

| | |

Magnesium Nitride Health & Safety Information |

| Signal Word | Warning |

| Hazard Statements | H315-H319-H335 |

| Hazard Codes | Xi |

| Risk Codes | 36/37/38 |

| Safety Statements | 26-36 |

| Transport Information | UN 2813 4.3/PG I |

Inquiry us