Silicon Carbide Powder Supplier

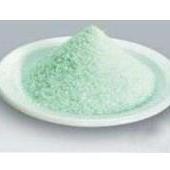

Silicon carbide is a chemically inert material used in many industries. It has a low co-efficient of thermal expansion, high strength at high temperatures and is corrosion resistant. It can be formed into ceramics, a polymer matrix or large crystals for use as semiconductors.

It is a common choice for electrical applications as it has a band gap of 2.4 eV or more. It can be doped with nitrogen, aluminum or boron to improve its conductivity. It also shows excellent properties at high temperatures, up to 1600 degC.

A silicon carbide powder supplier carries a full range of products including rough, macro-grits, micro-grits, powders, bonded abrasives and refractory materials. Its Mohs hardness of 9.25, chemical inertness, resistance to melting, high thermal conductivity and low co-efficient of thermal expansion make it a good choice for wire sawing, power switching, high temperature heating elements, refractories, sandpaper, grinding wheels, gem polishing, advanced ceramics, diesel particulate filters, and thermal sprays.

The surface morphology of the same specimen with different loads of silicon carbide at the different wt%s is shown in Figure 2. These samples were printed with a laser using island-like scanning lines instead of long scanning lines. The laser induced melt flow caused the material to be in a high deformation state that resulted in increased porosity and internal defects.

Workers who use carborundum abrasives frequently or work in the manufacturing of it may be susceptible to diffuse interstitial pulmonary fibrosis, which is characterized by fibrotic lung disease and lung cancer. Studies have found that these workers have a two-to fourfold increased mortality rate after adjustment for tobacco smoking.