Silicon Dioxide SiO2 powder CAS 7631-86-9

About Silicon Dioxide SiO2 powder:

Silica, also known as silicon dioxide, is a silicon oxide with the chemical formula SiO2. The most common form in nature is quartz and various organisms. In many parts of the world, silica is the main component of sand. Silica is one of the most complex and abundant material families, in the form of mixtures of various minerals and synthetic products. Notable examples include fused silica, fumed silica, silica gel and aerogel. It is used in structural materials, microelectronics (as electrical insulators), and components in the food and pharmaceutical industries.

Inhalation of finely divided crystalline silica is toxic and can cause severe inflammation of lung tissue, silicosis, bronchitis, lung cancer and systemic autoimmune diseases such as lupus and rheumatoid arthritis. High-dose inhalation of amorphous silica can cause non-permanent short-term inflammation, and all effects can be cured.

Long-range arrangement of silicon and oxygen atoms forms crystalline silica, short-range arrangement or long-range disordered arrangement forms amorphous silica. In a silicon dioxide crystal, the silicon atoms are at the center of a regular tetrahedron, and the four oxygen atoms are at the four corners of the tetrahedron. Many tetrahedrons are held together by oxygen atoms at the four corners. Each oxygen atom is shared by two tetrahedrons, that is, each oxygen atom is bonded to two silicon atoms.

The simplest molecular formula for silica is SiO2, but SiO2 does not represent a simple molecule (just the ratio of the number of silicon atoms to the number of oxygen atoms in the crystal of silica). Pure natural silica crystal is a hard, fragile, insoluble, colorless and transparent solid, often used in the manufacture of optical instruments. Feel free to send an inquiry to get the latest price if you would like to buy Silicon Dioxide SiO2 powder in bulk.

Performance of Silicon Dioxide SiO2 powder :

1 There are a lot of unsaturated surface residual button and different bonding state of hydroxyl groups, so it have high reactivity, easy to scatter;

2 Nano silicon oxides using sol-gel, synthesis of small, uniform particle size, controllable in the system, the use of different, can company of surface treatment packages, nano silicon powder can steadily in solvent system, form transparent or translucent sol colloid;

3 To ultraviolet light and presents high reflection characteristics of uv wavelengths (200 ~ 70% of the reflectivity 280nm) ~ 80%, For in the uv wave (280 ~ 80% of the reflectivity 400nm) ~85%, In visible (400-800nm) reflectivity 85%, The band of 800-1350 near infrared reflectance also higher than 70%.

Technical Parameter of Silicon Dioxide SiO2 powder :

Product | Nano silicon dioxide SiO2 powder | |

Analysis Project | Al,Fe,Ca,Mg,Cu,Mn,Na,Co,Ni,F.Si,Pb,K,N,C,S,F.O | |

Analysis Result | Chemical Composition | Wt%(Analysis) |

Al | 0.001 | |

Fe | 0.001 | |

Ca | 0.001 | |

Mg | 0.001 | |

Cu | N.D | |

Mn | 0.001 | |

Na | 0.001 | |

Co | 0.001 | |

Ni | 0.001 | |

F.Si | 0.001 | |

Pb | N.D | |

K | 0.001 | |

N | 0.005 | |

C | 0.002 | |

S | 0.004 | |

F.O | 0.050 | |

How is Silicon Dioxide SiO2 powder produced?

Preparation method of amorphous silicon dioxide

The preparation of amorphous silica includes five steps, namely the preparation of silica gel, granulation process, sintering process, cleaning process and drying process.

1. Preparation of silica gel

Crushing silicon tetrachloride can produce silica gel, or pulverizing organic silicon compounds (such as tetra methoxy siloxane) to produce silica gel, or using fumed silica can produce high-quality silica gel.

2. Granulation process

By drying the silicone gel into a dry powder, pulverizing the dry powder, and then performing classification, a silica powder with a desired average yield can be obtained.

3. Sintering process

The silica powder obtained in the granulation process is sintered at a temperature of 800°C to 1450°C. The spheroidization process of thermal plasma is used to introduce argon gas at a predetermined flow rate and convert the output at a predetermined frequency to generate plasma. In the plasma torch, the sintered and obtained silica powder is dispersed at a predetermined feed rate, and heated and melted at a temperature of 2000 ℃ to the boiling point of silica.

4. Cleaning process

After the spheroidization step, the fine powder adhering to the surface of the spheroidized silica powder is removed.

5. Drying process

After the above cleaning process, the silica powder is dried.

Applications of Silicon Dioxide SiO2 powder:

Silica is a raw material for manufacturing glass, quartz glass, water glass, optical fiber, important parts of the electronics industry, optical instruments, handicrafts and refractory materials, and important material for scientific research.

1. Silica is the main ingredient in most glass production. When other minerals melt with silica, the freezing point reduction principle reduces the melting point of the mixture and increases the fluidity. The glass transition temperature of pure SiO 2 is about 1475K. When fused silica SiO2 cools quickly, it will not crystallize but will solidify into the glass. Therefore, most ceramic glazes are mainly composed of silica.

2. Silica can also be used as an additive, an excellent flow promoter, mainly used as a pressurizing agent, anti-sticking agent, and glidant.

3. Silica is particularly suitable for the granulation of oils and extracts, and it can also use glidants in direct compression.

4. As a disintegrant, silicon dioxide can greatly improve the fluidity of the granules, increase the bulk density, and increase the hardness of the prepared tablets. It can be used as an internal desiccant in the manufacture of granules to enhance the stability of the drug.

5. Silica can also be used as a filter aid, scavenger, defoamer, suspending agent and thickener for liquid preparations.

6. About 95% of the commercial uses of silica (sand) occur in the construction industry, such as the production of concrete (Portland cement concrete).

7. In cosmetics, silica plays a certain role due to its light diffusion properties and natural absorption.

8. The process of passivating the silicon surface by thermal oxidation (silicon dioxide) is critical to the semiconductor industry. It is usually used to manufacture metal oxide semiconductor field-effect transistors (MOSFET) and silicon integrated circuit chips (using planar technology).

9. Silica can be used for the extraction of DNA and RNA because it can bind to nucleic acids in the presence of chaotropic agents.

10. Since silicon dioxide is a natural oxide of silicon, compared with other semiconductors such as gallium arsenide or indium phosphide, silicon dioxide is more widely used.

11. Silicon dioxide can be grown on the surface of silicon semiconductors. The silicon oxide layer can protect the silicon surface during the diffusion process and can be used as a diffusion mask.

Storage Condition of Silicon Dioxide SiO2 powder :

Nano silicon dioxide SiO2 powder should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.

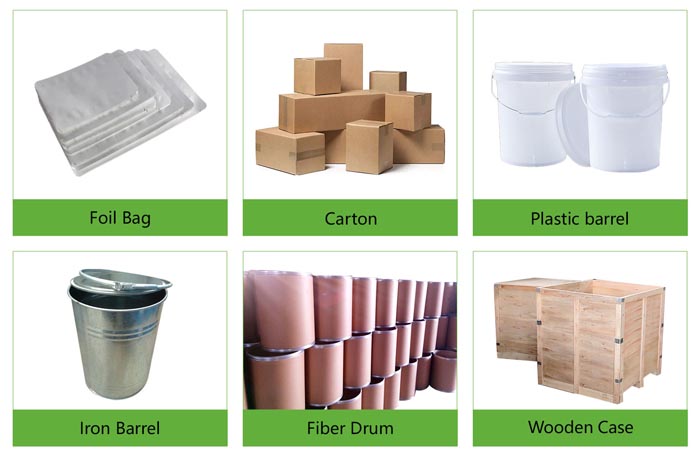

Packing & Shipping of Silicon Dioxide SiO2 powder :

It is packed in double plastic bags inside, which can be filled with argon in vacuum; it can be vacuumed and filled with argon for protection..

Silicon Dioxide SiO2 powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Silicon Dioxide SiO2 powder shipping: could be shipped out by sea , by air, by express as soon as possible once payment receipt.

Silicon Dioxide SiO2 Powder Properties | |

| Other Names | Fused quartz, silane, dioxo, Silicon (IV) Oxide, Cristobalite, Silica, Crystalline silica, Dioxosilane, Sand, Silica glass, SiO2, O2Si |

| CAS No. | 7631-86-9 |

| Compound Formula | SiO2 |

| Molecular Weight | 60.09 |

| Appearance | White Powder |

| Melting Point | 1,600° C (2,912° F) |

| Solubility in water | N/A |

| Density | 2533 kg/m3 |

| Purity | 99.5-99.9% |

| Particle Size | 10-30nm |

| Boling point | 2,230° C (4,046° F) |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | 59.9668 g/mol |

| Monoisotopic Mass | 59.967 Da |

Silicon Dioxide SiO2 Powder Health & Safety Information | |

| Safety Warning | Danger |

| Hazard Statements | N/A |

| Flashing point | Not applicable |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | NONH |

| WGK Germany | NONH |