Introduction of three types of nitride powder

Nitrides made from alkali metals or alkaline Earth metal elements are called ionic. They have crystals that are mostly ionic, and nitrogen is found in the form N3 - also known by the name salt-like nitrides. Li3N, the only ionic nitride currently used, is a deep red solid. Li3N belongs to the hexagonal crystalline system and is a red solid with a density of 1.27g/cm3 as well as a melting point 813degC. It is very easy to synthesize, and it has a good ionic conductivity. It can be combined either with solids or liquids. Coexistence of Lithium is currently the best solid-lithium electrolyte available.

Covalent nitride

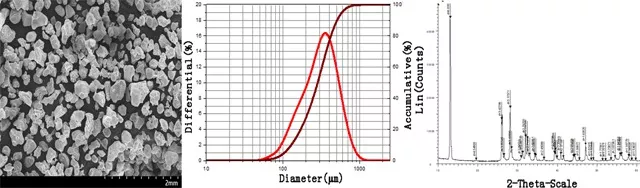

Covalent nitrides are formed when group IIIAVIIA element are combined. The majority of their crystals consist of covalent bonding. Nitrogen oxides and nitrogen halos are the correct names for compounds that oxygen, group VIIIA elements and nitrogen form. The covalent nitrides most commonly used are mainly the nitrides from group IIIA elements and IVA (such as AlN, GaN and InN). The unit of structure is similar to that of a diamond's tetrahedron, and so is known as class Diamond nitride. They have a high hardness and melting point. The majority of them are semiconductors or insulators. They are widely used for cutting tools and high-temperature ceramics.

Metal Nitride

These nitrides form by transition metal elements are metallic nitrides. The nitrogen atoms in these nitrides can also be called infill nitrides. The composition of this type nitride can vary, as the chemical formula does not have a strict ratio. Most metal-types nitrides have a NaCl type of structure and the chemical formula MN. In general, it is a metal-like material with properties such as high conductivity and hardness, high melting points, wear resistance resistance, corrosion resistant, etc. It is well suited for use in catalytic and electrode materials, as well as cutting materials.

(aka. Technology Co. Ltd., a global leader in chemical materials and nanomaterials with more than 12 year's experience as a supplier of high-quality chemicals. The nitride produced by our company is of high purity and has a low impurity level. Contact us if you need to.