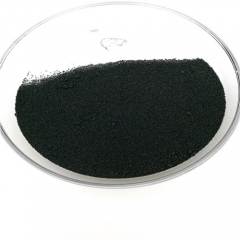

Introduction to Amorphous Boron Powder

Amorphous Boron Pulp is an odorless brown powder. This is due to the random order in which its boron atoms are bonded together. It is extremely hard and different from crystalline. According to 1979 international atomic weigh, the atomic weight for boron was 10.81. Its melting temperature is 2300 +-2 Fahrenheit:2550 . Specific gravity between 2.34 and 2.37

It is insoluble with water, hydrochloric Acid, ethanol, ether, but it is soluble in cold concentrated acid solution to decompose Hydrogen, which can also be used to oxidize hydrogen to boric acid using concentrated sulfuric acid or concentrated nitric acids.

Boron occupies an unusual position on the periodic table. It is a metal-non-metal combination with strong negative electric, small atomic radius and concentrated nuclear charge. Stable at room temperature; can be heated to 300F and burned at 700F; tasteless and odorless; non-metallic characteristics similar to silicon. Boron can interact with oxygen and nitrogen at high temperatures; can also be combined with other metals to make boride.

What does Boron Powder be used for?

Amorphous Boron's chemical properties are more active than those of crystalline Boron. Crystalline Boron is so hard that it's often used in place of diamond for cutting tools and drilling. Amorphous Boron powder is an important source of energy. Amorphous boron powder is a solid fuel for composite solid propellants. Its calorific values are more than twice those of carbon, aluminum, and magnesium. Its volumetric calorific worth is nearly three times that that of hydrocarbon fuel and it has a density that is just slightly less than that of aluminium. Boron should be the most non-metallic source of energy. Amorphous boron's ignition temperature is significantly lower due to its irregular shape, large specific surface area, and low melting point.

Amorphous Boron Powder material could be used for (not only but also)

1.It is an ideal solid fuel for composite solid propellant. The calorific worth of boron is nearly three times that of hydrocarbon fuels. Boron is the best nonmetallic fuel in terms of energy. Amorphous boron's ignition temperature drops dramatically due to its irregular shape and large specific area.

2. To prevent metals' oxidization at high temperatures

3.As part of an alloy to improve properties of metals.

You can use it as a compound, or as an additive to other alloys. Can be used in special alloy steel melting and smelting steel gas scavenger; electronic industry for atomic reactor control rod, rocket high-energy fuel; it is an important raw materials for the production of high purity Boron halide and the raw material to prepare various borides. Boron and its components can be used to replace precious and rare metals and as catalysts in organic chemical reaction.

Lanthanum bore, used in more then 20 military and high-tech industries, such as radars, aerospace, electronic industry instruments, instruments, medical devices home appliances, metalurgist, environmental protection, etc.

Boride Ceramics is widely used in the areas metallurgy electronics medicine ceramics nuclear industry chemical industry. It has higher wear resistance and corrosion resistance.

Magnesium Dboride Powder,MgB2 superconductor is the most critical temperature. Its superconducting temperature is 39K. -234 . Magnesium Diboride, a new superconductor material, opens up new possibilities for studying a new class of high-temperature semiconductors.

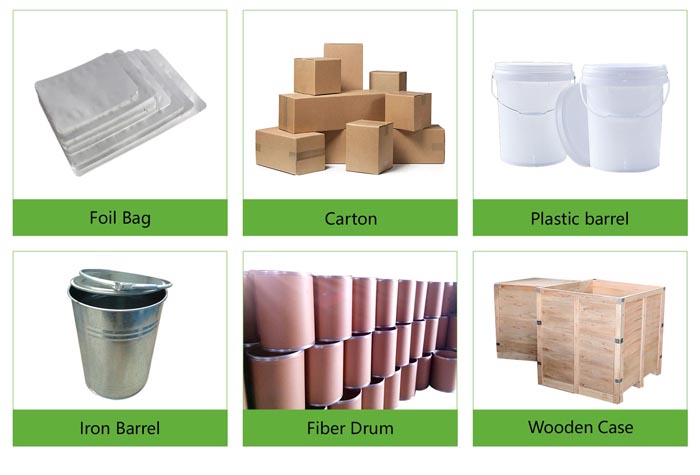

price of amorphous Boron powder

Price is affected by many factors, including supply and demand, industry trends and economic activity.

You can email us to request a quote for the latest Mohs Boron Powder price . (brad@ihpa.net)

Amorphous Boron powder supplier

Technology Co. Ltd. is a trusted global supplier and manufacturer of chemical materials. They have over 12 years experience in manufacturing super high-quality chemicals, such as silicon powder.

Send us an inquiry if you're looking for high quality Amorphousboron Powder. (brad@ihpa.net)