Aluminum Oxide Powder used as Carrier

What does it mean to be an aluminum oxide carrier

Aluminum oxide White powder, molded Aluminum oxide, solid is called carrier. It accounts for approximately 70% of industrial support catalysts. Aluminium oxide comes in many forms. Different forms not only have different properties; even different forms can exhibit different properties due to their different sources.Aluminum oxide is used as a catalyst. These properties are crucial. Aluminium oxide can be prepared mostly from the hydroxide. Also known as aluminum oxide, hydrate or Aluminum oxide hydrate.

Aluminum oxide carrier shapes

Although aluminum oxide carrier powders are available in commercial quantities, most are moldable. Most aluminum oxide carriers used for catalysts in fixed-bed reactions are spherical, ingot-shaped, and strip-shaped. However, microspherical aluminum oxygen carriers are most commonly used in fluidized beds reactors. Aluminum oxide can be made into specific-shaped carriers, including honeycomb and rings, for catalytic processes like trefoil, ring, or fiber. Aluminium oxide sol can also be purchased in solids. Crystal form, purity and specific surface area are important criteria for choosing aluminum oxide. Bulk density is also an option. Specific surface area for a-aluminumoxide is extremely low, less than 1m2/g. In contrast, the specific surface area for transition aluminum oxide ranges from 10102m2/g to up to 10102m2/g.Properties of aluminum oxide carriers

Porous materials make up most of the commercial aluminum oxide carriers. The pore sizes and their distributions have a significant impact on the diffusion properties in the catalytic processes. While fine pores have an average size of less than 20mm2, coarse pores are larger and can exceed microns. The species of pore can have a different pore structure. Every type of transition aluminium oxide is water-rich. Additionally, there are exposed aluminum atoms and hydroxyl groups at the surface. Temperature and the prep conditions can affect the surface acidity. Aluminum oxide will have a higher surface acidity due to the presence of halogen and other negative ions. These ions will also promote aluminum oxide's ability to catalyze hydrocarbon cracking or isomerization.Application of aluminum oxide powder

Catalytic active elements are added to aluminum oxide powder. Supporting catalyst active ingredients with high specific activities is possible with aluminum oxide having a limited specific surface area. This can be used for materials that have a few coarse pores. This type of carrier is able to eliminate pores' diffusion effects and reduce deep oxidation. The support for the oxidation from ethylene to an aluminum oxide catalyst is a-aluminum. A large surface area aluminum oxide can disperse active components easily into tiny particles. The barrier function of the carrier can prevent active components from sticking to the particles. This is the most widely-used aluminum oxide carrier. The aluminum oxide supports can be used to disperse precious metals like platinum, rhodium, and other metals.Aluminum oxide's aluminum surface acidity combined with the active components form bifunctional catalysts. Platinum-aluminumoxide catalyst for platinum reforming. Aluminum oxide acts not only as a carrier but is also an active component of the catalyst.

Aluminum oxide Powder Price

Price is affected by many things, such as the demand and supply in the market and industry trends. Economic activity and market sentiment are also important.Send us an enquiry to get the best price for aluminum oxide powder. (brad@ihpa.net)

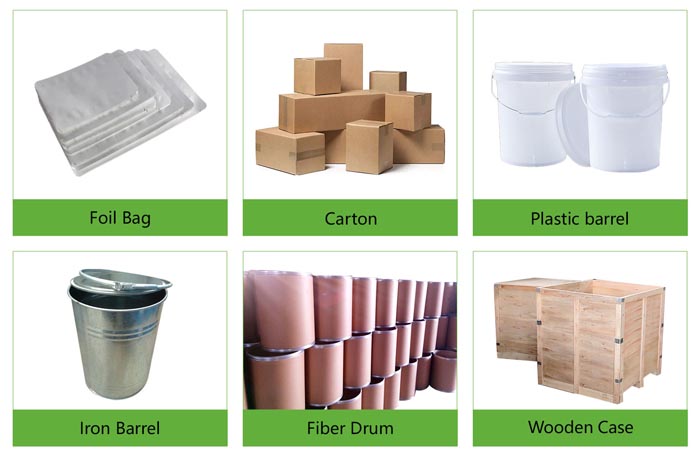

Aluminum oxide Powder Supplier

Technology Co. Ltd. (), is a well-respected aluminum oxide powder manufacturer, and supplier of Al2O3 powder with more than 12 years' experience. All of our products are available for shipment worldwide.You can contact me if you're looking for aluminum oxide powder of high quality. Get in touch You can also send us an inquiry. (brad@ihpa.net)