Titanium powder and its application

The alloying of titanium with elements like iron, aluminum vanadium and molybdenum can create strong and lightweight alloys used for applications such as aerospace military, agricultural processes, medical prostheses and implants, dental and surgical instruments and files, dental implant, sporting good, jewelry and mobile phones.

Titanium and titanium alloy Powder

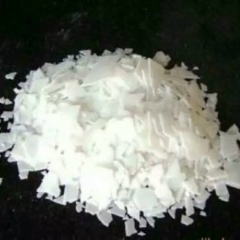

The metal powder titanium has many uses. Titanium is a silvery-gray irregular metal powder with a high suction capacity. Titanium powder metallurgy offers the ability to produce clean, or near-clean, shaped parts. This is without the cost and material loss associated with machining parts from billets. Powders can undergo elemental blending, pre-alloying, and are then cured through metal injection moulding, hot isostatic press, direct powder forming, or laser engineering mesh formation.

Titanium and titanium alloys have excellent overall performances and are widely used for SLM and EBM. The best metals for 3D printing are titanium spherical particles. These powders are widely used to create high-strength materials.

Titanium powder It has been used for many years as an alloying material for different applications. With it, you can create net shape parts without any or minimal material losses that come with intricate parts created with wrought billet.

The traditional method of extracting titanium powder This process is called the Kroll method. This technique is based on a temperature of up to 1040degC, and includes a number of sub-processes, such as hot isostatic press, alloying and other processes. To produce pre-alloyed Titanium powder, further methods must be used. To remove contaminants, the material is subjected the hydride/dihydride procedure, vacuum hot pressing and final vacuum annealing. A number of metal consolidating strategies must be used to create the final product. Powder injection moulding or metal injection molding is a long-established and cost-effective method of fabricating small-sized metals to large quantities. There is also the direct powder-rolling process, which is used for the production and manufacture of sheets and plates. The laser-engineered network shaping technique can be used to quickly fabricate, enhance, and repair metal components. The components are subjected to hot isostatic presses, which are performed at high temperatures and pressure, in order to consolidate the titanium powders. To achieve the final product spark plasma sintering (also known as electric current assisted sintering) is used. This produces titanium powder with good mechanical characteristics and good grain sizes, without unwanted grain growth.

Titanium powder Application

The use of titanium powder Printing 3-dimensional auto parts is the latest breakthrough in metal manufacturing. Through 3D-printing, it is possible to produce different components and parts for automobiles, aerospace frames, and engines. Titanium is still used for metal injection molding as well as powder metallurgy.

(aka. Technology Co. Ltd., a trusted global chemical supplier and manufacturer has over 12 years experience in providing super-high-quality chemicals. The Titanium powder Please note that the products produced by our company are of high purity and have low impurities. Please. Contact us if necessary.