Melting Point of Iron in Fahrenheit

melting point of iron in fahrenheit

The melting point of a substance is the temperature at which the solid and liquid can exist in equilibrium. It is also known as the liquefaction point or freezing point. It is usually specified at standard pressure and is a thermodynamic property of a material.

Why does the melting point of a metal change?

The melting points of various metals vary widely depending on their applications. These temperatures are important to understand if you're working with a particular metal, as they can have a direct impact on your project or end-use.

A metal's melting point is the temperature at which its molecular structure changes from a liquid to a solid state, or vice versa. This is a property of its chemical bonding and it's the result of the forces that occur between molecules and atoms when they are heated.

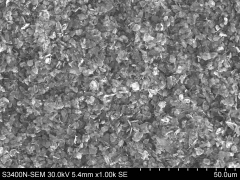

Iron - the fourth most common element on Earth (found in group 8 and period 4 of the periodic table) is an lustrous, ductile, silver-gray metal with four distinct crystalline forms. It rusts in damp air but does not corrode in dry air and is easily dissolved in dilute acids.

Steel - PURE IRON PLUS ADDED BITS

In the case of steel, the added bits are most commonly carbon. They make it stronger, more resistant to corrosion and easier to fabricate. As such, it has a lower melting point than pure iron.